There is a variety of products to choose from, so you can find what you need. Prefillable syringes filling and closing machine factory,

soap cartoning machine factory, Automatic Electronic Counting Machine wholesale, High speed following capping machine supplier, Labeling Machine manufacturer, ZHTB60 Tube Labeling Machine wholesale, Welcome all customers of home and abroad to visit our company, to forge a brilliant future by our cooperation., Maldives, Our company adheres to the spirit of "lower costs, higher quality, and making more benefits for our clients". Employing talents from the same line and adhering to the principle of "honesty, good faith, real thing and sincerity", our company hopes to gain common development with clients from both at home and abroad! Most Bag Packing Machines track and adjust various mechanical parameters through intelligent control instruments and men

With the increasingly fierce competition in the manufacturing and production of plastic bottles in the food and pharmace

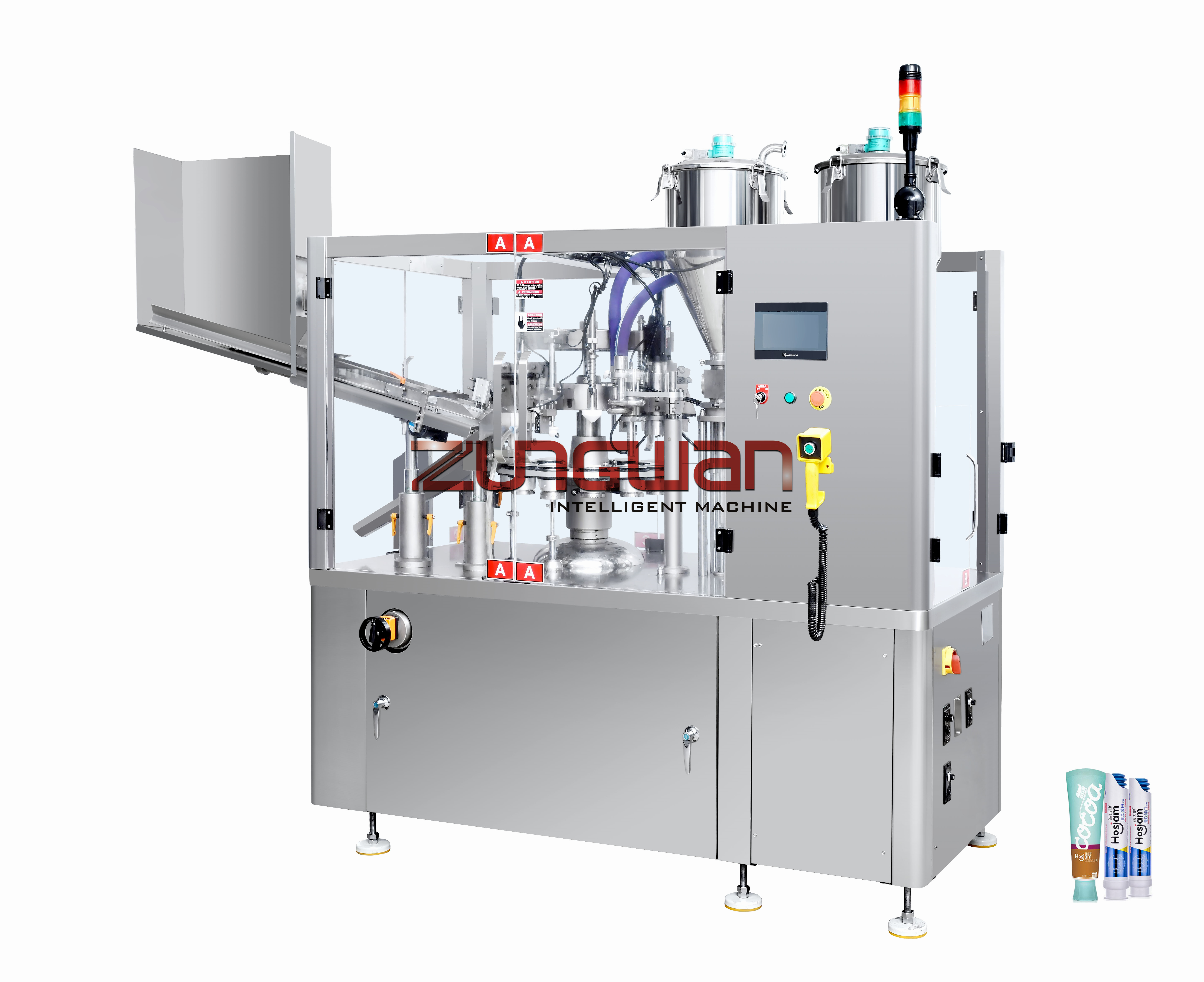

Wenzhou Zungwan Intelligent Machine Co.,Ltd. is the professional equipment manufacturer to keep researching and developi

In our daily life, Capping Machine plays a vital role for us, so what are the main work processes and precautions of the

Wenzhou Zungwan Intelligent Machine Co.,Ltd. is the professional equipment manufacturer to keep researching and developi

Pharmaceutical Filler and Capper have been used by more and more companies in the industry, and many operators have lear

Bottle Unscrambler is suitable for automatic unscramble of plastic round bottles, flat bottles, and tube-top bottles. Di

The tube Filling machine And the Sealing machine are determined by multiple parameters. It is impossible to describe a T

Packaging machine for classic flat pouches. Packaging machine for packaging piece-dosed products into a bag sealed from all four sides. Output: 60–80 bags/min.

Automate your production with a bottle filling plugging capping labeling machine from . Browse through filling machines and choose the machine your business needs.

27/7/2021· New Manual 5-50ml Liquid Filling Machine Cream Paste Shampoo Buy New Manual 5-50ml Liquid Filling Machine Cream Paste Shampoo Cosmetic Filler: Parts

Capsule Filling Machine Exporter Lodha is well known Capsule Filling Machine manufacturer in India. We have a wide range of Encapsulation

Reform Packaging Machine offers a wide range of machines providing numerous solutions for your milk powder packaging needs. Reform years of hands-on experience, enables it to offer various innovative packaging solutions on its VFFSM and HFFSM manufactured with your needs in mind. Related bag style 4 Side Seal Stickpack Center Sealed Bag Quadro Pack

10Automatic Aluminum Tube Filling And Sealing Machine with Cover Pcs 1.High-tech product which successfully developed and designed by adopting advanced technology from abroad and strictly meet GMP requirement.

Automatic Linear Screw Capping Machine Approx Price: ? 500,000 Output/Hour: 7200 bottles. Direction of Movement: Left to Right No. of Sealing Roller: 6 Nos. Height of Conveyor: 860 mm to 910 mm Machine Dimension: 2000 L x 900 W… Read More Automatic Twelve Head ROPP Screw Capping Machine Approx Price: ? 850,000