We are a big platform for cross-border shopping. Enamel Filling & Plugging And Capping Machine wholesale,

automatic filling and plugging machine, cosmetic tube filling and sealing machine, Pharmaceutical Filling And Capping Machine wholesale, Horizontal Around Bottle Labeling Machine factory, Liquid Filling Machine corrosion inhibitor supplier, Therefore, we can meet different inquiries from different consumers. You should find our web page to check additional info from our products., Auckland, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality items we offer, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We are confident that we'll share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries. Wenzhou Zungwan Intelligent Machine Co.,Ltd. is the professional equipment manufacturer to keep researching and developi

They ordered two hand sanitizer filling lines, requiring a speed of 150 bottles per minute, from automatic bottle manage

In our production and life, the Liquid Filling Machine has a significant impact on many industries, so what is the metho

Liquid Filling Machine is a kind of process machinery, its process characteristics are more obvious, for the design requ

Liquid Filling Machine is specially designed for filling easy-to-open bottles. It has a reasonable design, simple struct

Tube Filling machine And Sealing machine is advanced equipment for sealing plastic pipes and aluminum-plastic pipes. It

Cartoning Machine effectively guarantees the packing quality of items and the safe operation of the mechanismWe know tha

Tube Filling machine And Sealing machine adopt the latest module circuit, stable working performance, high efficiency, a

Food Packaging Business Since 1997 Food Packaging Machine Food-Packaging …

Enamel filling Unlike in soft enamel pins, each cavity of a hard enamel pin is overfilled with enamel. Also, note that the enamel filling happens before electroplating in this process. 2. Baking Hard enamel pins are baked after each color of enamel is added. So if a pin has five unique colors, it will be baked five times. 3. Polishing

Npack offers a wide range of packaging solutions for pills, powders, liquids and other pharmaceutical products. We supply auger, vibratory, and piston filling machines. Each of them ensures your items are packaged quickly and accurately. We know each customer’s needs are different. That’s why we’ll work closely with you to create the ...

Automatic liquid packaging machine is suitable for the sachet / bag / pouch packaging of variety of liquids,slurries,pastes, such as water, juice, Honey, cream, sauce, milk, reagent, pesticide emulsion, dyes, pigments and etc. VIEW MORE Snus Packing Machine Snus packing machine suitable for packing snus granule or snus powder.

full pneumatic liquid filling machine for shampoo on sale manufacturers, find details about full pneumatic liquid filling machine for shampoo manufacturers, supplier and wholesaler - …

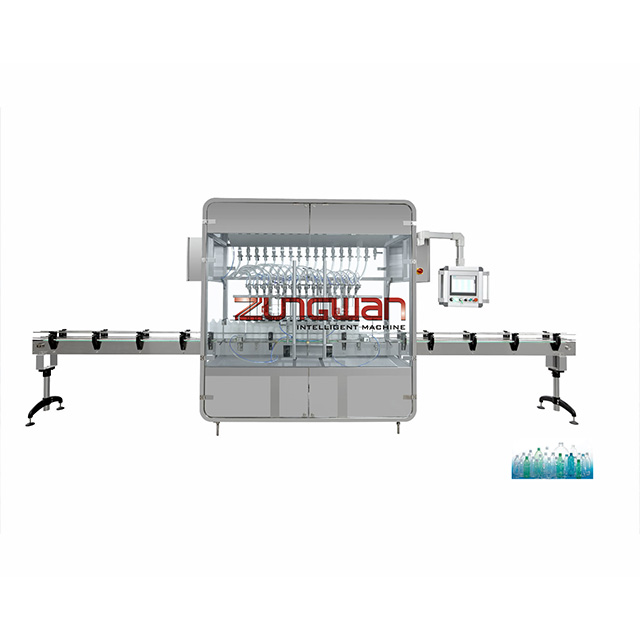

1、Linear design , automatic filling and capping on one machine. 2、Piston pump filling system for both liquid and cream , no drip , no tail. 3、PLC and HMI control control for different filling volumes for easier adjustment and setting. 4、No bottle no filling ,n...

Factory Price Silicone Sealant Filling Machine High Viscosity Glue Filler Plastic Cartridge Filling Machine.