continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for cosmetic tube filling and sealing machine wholesale,

cartoner machine manufacturers, tube filler and sealer factory, Jar Filling And Capping Machine supplier, Bottle Big Stand Labeling Machine supplier, Liquid Piston Filler, We generally hold the philosophy of win-win, and build long-term cooperation partnership with clients from throughout the earth.We believe that our growth base on customer's achievements, credit history is our lifetime., Bangalore, In order to make more people know our products and to enlarge our market, we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way. They ordered two hand sanitizer filling lines, requiring a speed of 150 bottles per minute, from automatic bottle manage

Tube Filling machine And Sealing machine is advanced equipment for sealing plastic pipes and aluminum-plastic pipes. It

Celebrate the 10th anniversary of ZUNGWAN intelligent machinery——A letter from central machinery to youHello, partners,

Korea East Asia Pharmaceutical Company, ordered a syrup filling line from our company, from bottle management - bottle w

Pharmaceutical Filler and Capper have been used by more and more companies in the industry, and many operators have lear

Speaking of Bag packaging machines for large machinery, it is necessary to briefly talk about the knowledge of stand-up

Liquid Filling Machine is used in the beverage, drinking water, and liquor industries and has become a very important eq

The Cosmetic Filling Machine and Capping machine is a professional cosmetic filling and capping equipment, which can mak

As a leading cartoner machine manufacturer, BW Integrated Systems strives to produce a simple machine with advanced features to ensure you find the proper solution. Cartoning Machine Applications The various features of BW Integrated Systems’ horizontal and vertical cartoners allow them to be used for many industries and applications.

Enamels are applied by sifting dry particles onto the surface of your metal or to previous enameled layers. Enamel powder can be wetted and used to fill depressions (champlevé) or enclosures (cloisonné). This technique is …

Piston Pump Filler Advantage 1. Comply with cGMP, the pharmaceutical manufacturing specification. Use SUS316 or 316L corrosion resistant stainless steel. 2. Comply with food manufacturing specifications, uses sanitary …

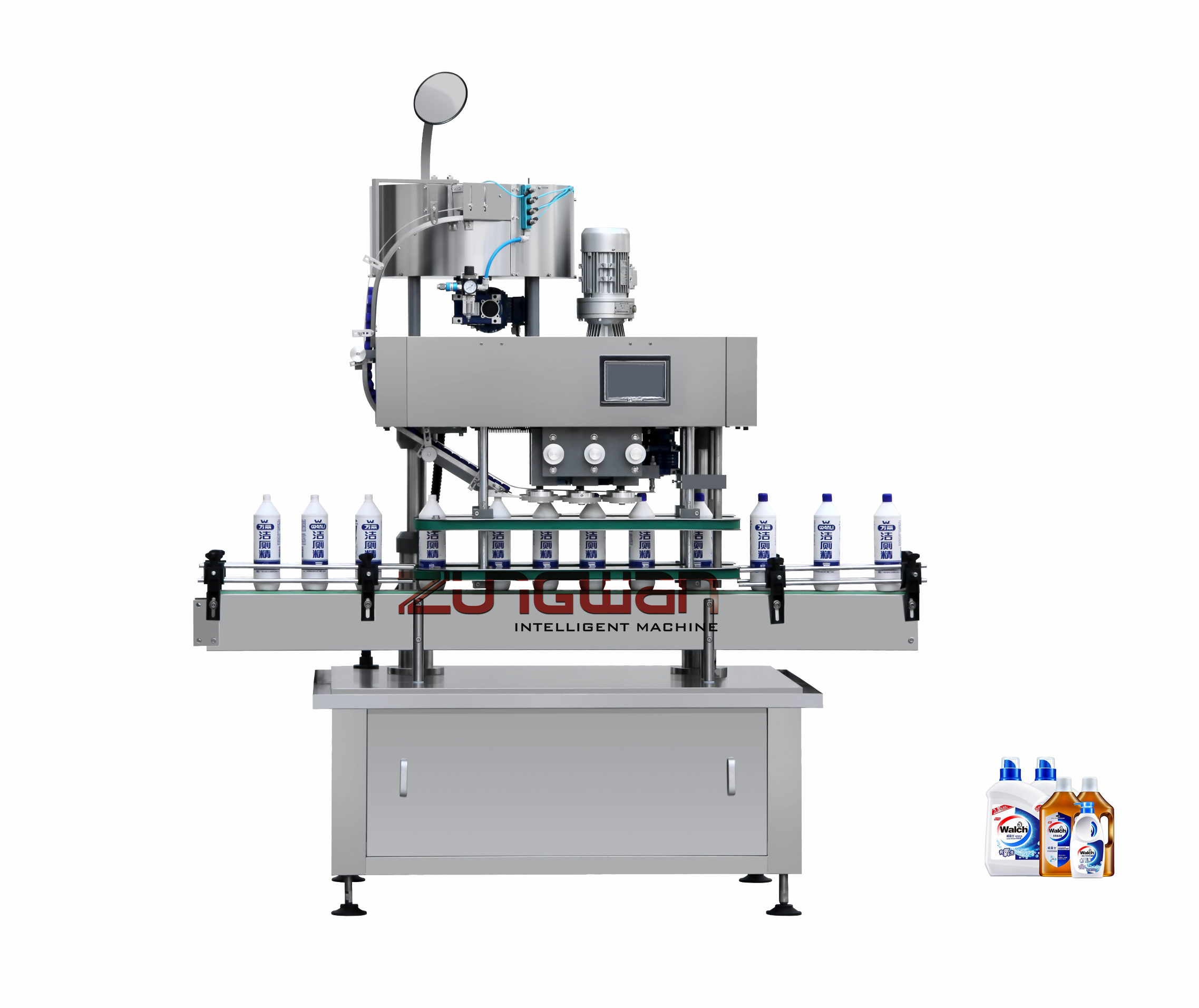

Filling Capping and Labeling Machine Total 55 Filling Capping and Labeling Machine Products 3 / 3 Video Automatic Desktop Oil Hand Sanitizer Bottle Liquid Soap Semi Automatic Filling Capping Labeling Machine FOB Price: US

Suitable for filling liquids like syrups, suspensions, serums, oils, paints, inks and lotion Technical Specification Speed Count3Stroke Count8, 16

Coffee Sachet Packing Machine. Auger Vffs Bagger Pillow Type Powder. Potato Chips Packing Machine. Doypack Packing Machine. Small Food Packing Machine. Packaging Machine From …

LIENM Automatic 30g 50g cosmetic glycerin filling machine cream jar filling and capping machine

High quality Calamine Lotion Filling And Capping Machine factory from China, China's leading Calamine Lotion Filling And Capping Machine product market, With strict quality control Bottling Production Line factories, Producing high quality Bottling Production Line products.