Wenzhou Zungwan - Packaging Machinery Equipment Manufacturers

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-30 Origin: Site

Imagine a packaging line where bottles are sorted flawlessly, without human error. This is the promise of automatic bottle unscramblers. These machines revolutionize modern packaging by efficiently sorting and orienting bottles, eliminating manual labor. In this post, you'll learn what bottle unscramblers are, their significance in packaging lines, and the key benefits they offer.

Automatic bottle unscramblers consist of several key components working together to sort and orient bottles efficiently for production lines. Understanding these parts helps grasp how the machine boosts packaging speed and accuracy.

At the start, bottles enter through the supply system, typically a vibrating hopper or disk made from stainless steel. This hopper uses high-frequency vibrations to move bottles along spiral tracks or guide grooves. The vibration gently separates the bottles, preventing clumping and ensuring they move smoothly into the next stage.

Once bottles leave the supply system, they enter the separation and orientation stage. Several mechanisms are common:

● Centrifugal Turntable: A fast-spinning disk uses centrifugal force to push bottles outward. Upright bottles stay on the turntable, while incorrectly positioned ones fall off and return to the hopper. Guide rails help direct upright bottles to the conveyor.

● Paddle or Star Wheel: Multiple rotating paddles grab bottles. They orient them by exploiting differences in bottle shapes, such as mouth and base diameters.

● Photoelectric or Mechanical Sensors: Fiber optic sensors or cameras detect bottle direction. If a bottle is upside down or misaligned, mechanical pushers or rotating clamps flip it to the correct position.

After orientation, bottles move onto the conveying system. This usually involves a conveyor belt made of PU or PVC with side guardrails to prevent bottles from falling. Transition guide rails are installed at junctions to avoid jams or tipping.

The entire system is managed by a programmable logic controller (PLC) paired with a human-machine interface (HMI). Operators can adjust vibration intensity, turntable speed, sensor sensitivity, and switch between bottle types easily. This flexibility allows the unscrambler to handle different bottle shapes and sizes efficiently.

1. Loading: Bottles enter the vibrating hopper, which separates and feeds them upward.

2. Screening: Bottles reach the spinning turntable. Upright bottles remain stable; others are thrown off and recycled.

3. Orientation: Correctly positioned bottles move to the conveyor. Misaligned ones are flipped mechanically.

4. Verification: Sensors check bottle orientation. Incorrect bottles are rejected and sent back.

This coordinated process ensures bottles are correctly aligned and spaced for subsequent filling, labeling, or packing steps, reducing downtime and errors.

Tip: Regularly calibrate sensors and adjust vibration settings to maintain optimal bottle separation and orientation, minimizing production interruptions.

Automatic bottle unscramblers transform production lines by speeding up sorting and organizing bottles. They replace manual labor, which is often slow and prone to errors, with a fast, reliable machine that handles thousands of bottles per hour.

Before these machines, workers sorted bottles by hand. This was tedious and inconsistent. Now, the unscrambler automatically separates and aligns bottles, ensuring each one is upright and correctly positioned. It uses vibrations, sensors, and mechanical arms to do this quickly. This automation means fewer mistakes and faster preparation for filling or labeling.

Bottlenecks happen when bottles pile up waiting to be processed. An automatic bottle unscrambler prevents this by maintaining a smooth, continuous flow. It feeds bottles evenly into the next machine, whether it's a filler, capper, or labeler. This keeps the entire line moving efficiently and reduces downtime.

A steady flow is crucial for high-speed production. The unscrambler's control system adjusts speed and sorting based on real-time conditions. For example, if the downstream machine slows, the unscrambler can pause or slow down to avoid overloading. This flexibility keeps production balanced and efficient.

Imagine a line processing 100 bottles per minute. Manually sorting might slow this to 60 bottles, causing delays. An automatic unscrambler restores full speed, increasing output by over 60%. This boost can translate to thousands more bottles processed daily, improving profitability.

Automatic bottle unscramblers play a crucial role in cutting labor costs and minimizing errors on production lines. By automating the bottle sorting and orientation process, these machines reduce the need for manual intervention, which often slows production and introduces mistakes.

Manually sorting bottles is time-consuming and physically demanding. Workers must pick, orient, and feed bottles one by one, which can lead to fatigue and slower output. Automatic unscramblers take over this repetitive task, handling thousands of bottles per hour without breaks. This reduces the number of employees needed for sorting, allowing companies to reallocate labor to more skilled roles or reduce overall workforce expenses.

Human error in bottle orientation can cause jams, misfeeds, or product defects downstream. Automatic unscramblers use advanced sensors and mechanical systems to ensure each bottle is correctly aligned and positioned before entering the filling or labeling machines. This consistent accuracy reduces downtime caused by jams or rejects and maintains product quality throughout the packaging process.

By cutting labor requirements and reducing errors, companies save significantly on operational costs. Less manual handling means fewer workplace injuries and lower training expenses. The reduction in product waste due to misaligned bottles also adds to cost savings. These machines pay for themselves over time by increasing line uptime and improving resource allocation.

Example: A bottling facility that replaced manual sorting with an automatic unscrambler saw labor costs drop by 30%, while production errors decreased by 25%, resulting in smoother operations and higher profitability (example data, verify for your context).

Automatic bottle unscramblers help manufacturers boost production output and scale operations efficiently. They handle the critical task of sorting and orienting bottles quickly, ensuring the packaging line runs smoothly at high speeds.

One big advantage of these machines is their ability to manage different bottle shapes and sizes. Whether round, square, or uniquely shaped bottles, an unscrambler can be adjusted easily to accommodate them. This flexibility means operators can switch production lines without long downtime or costly equipment changes. Many unscramblers feature tool-free adjustments and programmable settings, making transitions between bottle types quick and simple.

Production demands often fluctuate. Automatic bottle unscramblers allow companies to respond swiftly by scaling throughput up or down. The control system can modify sorting speed and orientation processes based on real-time production requirements. This adaptability helps prevent bottlenecks during peak demand and saves energy when output needs are lower. Plus, unscramblers integrate well with other automated equipment, creating a cohesive system that grows alongside the business.

By automating bottle unscrambling, manufacturers reduce manual handling and errors, leading to continuous, high-speed operation. This automation minimizes downtime caused by jams or misfeeds. The steady, reliable flow of bottles ensures downstream machines like fillers and labelers operate at full capacity. As a result, production lines achieve maximum throughput and consistent quality.

Imagine a beverage company handling multiple bottle sizes for different drinks. Using an automatic unscrambler, they switch between products in minutes rather than hours. The machine adjusts settings automatically, maintaining a production speed of 150 bottles per minute. This flexibility allows the company to meet diverse customer demands efficiently while maximizing equipment use.

When adding an automatic bottle unscrambler to your production line, keeping it running smoothly is key. Proper maintenance and thoughtful planning ensure the machine delivers consistent performance and long-term value.

Automatic bottle unscramblers involve mechanical parts, sensors, and control systems that need routine care:

● Cleaning: Dust, debris, or bottle residue can build up in the hopper, turntable, and conveyor. Regular cleaning prevents jams and maintains hygiene, especially important in food or pharmaceutical lines.

● Lubrication: Bearings, gears, and moving parts require periodic lubrication to reduce wear and tear. Follow manufacturer guidelines for frequency and lubricant type.

● Sensor Calibration: Optical or mechanical sensors must be calibrated regularly to detect bottle orientation accurately. Misaligned sensors lead to sorting errors or machine stoppages.

● Inspection: Routine checks for loose bolts, worn belts, or damaged components help catch issues early. Replace worn parts promptly to avoid costly downtime.

● Software Updates: Keep the control system’s software up to date to benefit from improved features and bug fixes.

Scheduling maintenance during planned downtime minimizes production impact. Training operators to perform basic checks and cleaning daily can also improve reliability.

Implementing an automatic bottle unscrambler requires upfront capital. Consider these cost factors:

● Machine Price: Costs vary based on capacity, bottle compatibility, and features. Higher-end models with advanced sensors or quick-change tooling may cost more.

● Installation: Integrating the unscrambler into your existing line may require modifications, conveyors, or control system connections.

● Training: Operators and maintenance staff need training to use and care for the machine effectively.

● Spare Parts: Budget for spare parts to ensure quick repairs and minimize downtime.

Despite the initial expense, the efficiency gains, labor savings, and error reduction often justify the investment over time.

Seamless integration is vital for maximizing the unscrambler’s benefits:

● Compatibility: Verify the machine supports your bottle sizes, shapes, and production speed.

● Control Systems: Ensure the unscrambler’s PLC or control interface can communicate with upstream and downstream equipment for synchronized operation.

● Space Requirements: Measure available floor space to accommodate the unscrambler and any necessary conveyors or access areas.

● Flexibility: Choose models with adjustable settings or modular designs to adapt to future production changes.

● Safety Compliance: Confirm the machine meets industry safety standards and fits your facility’s safety protocols.

Planning integration carefully reduces installation time and avoids production disruptions.

Selecting the right automatic bottle unscrambler is key to maximizing production efficiency and ensuring smooth operations. Here are the main factors to consider during your decision-making process.

Start by defining your production requirements clearly. Consider:

● Output Capacity: How many bottles per minute does your line need to handle?

● Bottle Types: What shapes, sizes, and materials are involved? Round, square, plastic, glass?

● Line Integration: Does the unscrambler need to fit into an existing line? What are the space constraints?

● Product Sensitivity: Are there hygiene or contamination concerns requiring stainless steel or GMP-compliant materials?

Knowing these details helps narrow down models that fit your specific operation and avoid over- or under-specification.

Next, analyze the technical specs of potential machines. Key parameters include:

● Sorting Speed: Ensure the unscrambler can meet or exceed your required throughput.

● Orientation Accuracy: High precision reduces jams and misfeeds downstream.

● Adjustability: Look for machines with easy-to-use controls for changing bottle types and sizes quickly.

● Sensor Technology: Advanced sensors improve detection and reduce errors.

● Automation Features: Some unscramblers offer automatic rejection of misaligned bottles or self-adjusting mechanisms.

Reviewing these specs ensures the machine delivers reliable, consistent performance aligned with your production goals.

A reputable manufacturer provides peace of mind through:

● Product Quality: Trusted brands offer durable, well-engineered machines.

● Customer Support: Timely technical assistance, spare parts availability, and maintenance services are vital.

● User Training: Good brands often provide operator training to maximize machine efficiency.

● Warranty and Service Contracts: These reduce risks and help maintain uptime.

Check reviews, request references, and consult industry peers to identify brands known for reliability and strong support.

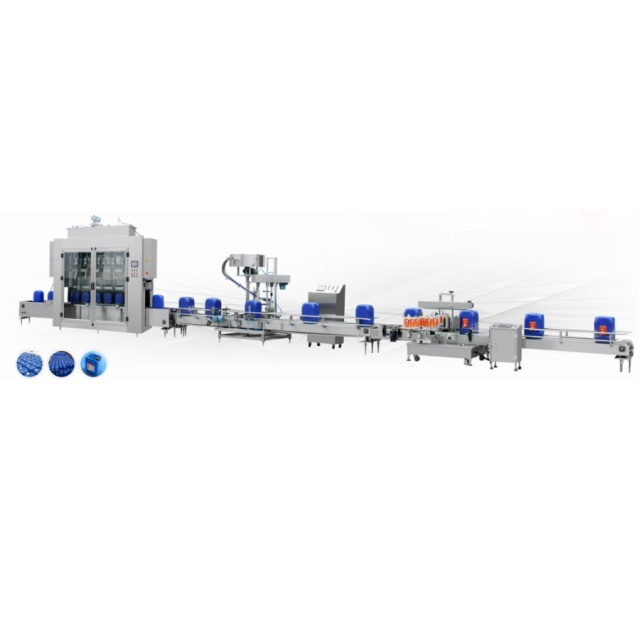

Automatic bottle unscramblers enhance production efficiency by automating sorting, reducing errors, and minimizing labor costs. They ensure a steady flow of bottles, adapting to various shapes and sizes, and increasing output. As manufacturing evolves, these machines will continue to play a vital role in streamlining operations and boosting productivity. Companies like Wenzhou Zungwan Intelligent Machine Co.,Ltd. offer advanced unscramblers that provide unique benefits, such as precision and flexibility, ensuring long-term value and improved production capabilities.

A: A Bottle Unscrambler is a machine that automatically sorts and orients bottles for efficient processing on production lines.

A: A Bottle Unscrambler uses vibrating hoppers, centrifugal turntables, and sensors to separate, orient, and convey bottles correctly.

A: Bottle Unscramblers boost efficiency, reduce labor costs, minimize errors, and ensure a steady flow of bottles in production lines.

A: Costs include the machine price, installation, training, and spare parts, offset by efficiency gains and labor savings.

A: Bottle Unscramblers are faster, more accurate, and consistent, reducing downtime and increasing production output compared to manual sorting.