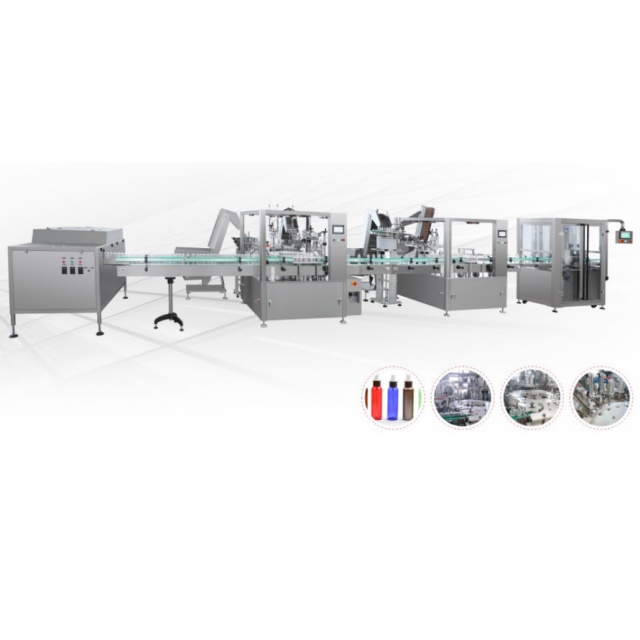

Perfume Filling Machine

ZUNGWAN - Your Trusted Perfume Filling Machine Manufacturer for Smart, Precise, and Elegant Packaging

Product Center

Overcoming Perfume Filling Challenges with ZUNGWAN Machine

Perfume manufacturers often face challenges such as uneven liquid levels, bubbles during filling, spillage, and frequent downtime when switching bottle sizes. Manual or semi-automatic machines struggle to maintain precision and consistency, especially for alcohol-based or high-value fragrances. ZUNGWAN solves these problems with its intelligent vacuum perfume filling machine, engineered for bubble-free, accurate, and stable performance. The modular design adapts to multiple bottle types (5–120 ml), while automatic bottle detection prevents waste and errors. With ±1% filling accuracy and an all-in-one structure, ZUNGWAN delivers cleaner results, faster operation, and long-term reliability for every production line.

Key Features of ZUNGWAN Perfume Filling Machine

ZUNGWAN - Your Trusted Perfume Filling Machine Manufacturer for Smart, Precise, and Elegant Packaging

High-Precision Vacuum Filling

ZUNGWAN adopts a low-pressure vacuum system that eliminates bubbles and ensures a clean liquid surface. With a ±1% filling accuracy and > 99% qualified rate, it guarantees consistent volume for every bottle — ideal for premium, alcohol-based fragrances.

Modular & Flexible Design

The system easily adjusts to fill 5 – 120 ml bottles with different shapes and neck sizes. Quick-change modules enable fast line conversions, reducing downtime for OEM or multi-SKU perfume producers.

All-in-One Automation

Integrated functions—bottle sorting, filling, capping, labeling, and collecting—streamline production. Automatic bottle detection and “no-bottle-no-fill” control minimize waste, ensuring stable output at 30 – 50 bottles per minute.

Application

Perfume & Fragrance Production Lines

OEM & Contract Filling Facilities

Small-Scale or Boutique Perfume Studios

OEM Service

Consultation & Requirement Analysis

Our engineering team works closely with you to understand your filling needs — bottle size, viscosity, production speed, and automation level. We evaluate your current line and provide a tailored technical proposal within 3–5 working days.

Custom Design & Prototype Confirmation

Based on your specifications, ZUNGWAN designs a customized perfume filling solution, including nozzle type, vacuum system calibration, and bottle-handling modules. A prototype or detailed 3D layout is shared for confirmation before production begins.

Manufacturing & Quality Assurance

Each OEM system is produced under ISO9001-certified standards. Precision machining, vacuum pressure testing, and 100% performance inspection ensure reliability and compliance with CE safety standards.

Installation, Training & After-Sales Support

ZUNGWAN provides remote installation guidance, operator training, and lifetime technical support. Spare parts and maintenance services are available globally, ensuring long-term efficiency and stability of your production line.

Why Choose ZUNGWAN

ZUNGWAN - Your Trusted Perfume Filling Machine Manufacturer for Smart, Precise, and Elegant Packaging

Global Customer Trust

Trusted by 500+ clients worldwide, including 100+ domestic and 400+ international partners — proving our global reputation in packaging machinery.

Strong R&D and Innovation

With over 20 patents for invention and utility models, ZUNGWAN leads in design innovation and customized filling technology.

Certified Quality & Safety

All machines are manufactured under ISO 9001 standards, and key models are CE-certified, ensuring consistent performance and compliance.

Comprehensive Product Capability

ZUNGWAN provides one-stop packaging solutions for liquids, creams, powders, and semi-fluids — meeting diverse industry needs with precision and efficiency.

FAQs

Related Blogs

2024 Beautyworld Middle East - Exhibition in Dubai

We are thrilled to announce our participation in the 24th Dubai Beauty event, where we will showcase our state-of-the-art fully automatic perfume filling and capping machine. This machine is engineered to handle various bottle sizes and shapes, thanks to its adjustable molds. It features an air cleaning system to ensure bottles are dust-free before filling.Equipped with four filling heads, three of which utilize a servo ceramic pump system, the machine offers high filling accuracy and easy adjustments via the HMI.

Read MoreHow Does Liquid Filling Machine Work

Discover how a Liquid Filling Machine works, including types, operation steps, and tips for accurate, efficient, and safe liquid filling in various industries.

Read MoreHow To Clean Liquid Filling Machine

Maintaining a Liquid Filling Machine is essential for any production facility handling beverages, pharmaceuticals, cosmetics, or chemical liquids. These machines are designed for precision and high-speed operations, but without proper cleaning and maintenance, performance can drop significantly

Read More

Get Touch With Us

Contact Info

If you have any questions or requirements regarding solutions, please feel free to contact our customer service team.

+86-13857753753/+86-13566223503/+8613732098198

E-mail: loro@cnzpack.com/pack@cnzpack.com/info@cnzpack.com