Wenzhou Zungwan - Packaging Machinery Equipment Manufacturers

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-01 Origin: Site

Imagine a world where packaging lines move seamlessly, without delays or errors. High-speed bottle unscramblers make this a reality, revolutionizing packaging automation by efficiently organizing bottles. In this post, you'll learn how these machines enhance production efficiency, ensure quality, and reduce costs across various industries. Discover the transformative benefits of high-speed bottle unscramblers in modern manufacturing.

A bottle unscrambler is a machine designed to organize bottles arriving in a random, jumbled state and prepare them for the next steps in packaging. It takes a chaotic pile of containers and arranges them in a single file or specific pattern. This ensures smooth movement down the production line, preventing jams and downtime. It’s essential for packaging automation, helping maintain a steady flow and consistent orientation of bottles.

The process starts by feeding bottles into the machine, usually in bulk. The unscrambler then sorts and orients them, aligning each bottle upright or in the required position. This is done through mechanical guides, rotating discs, or rails depending on the machine type. After sorting, bottles move onto the next stage, such as filling or labeling, perfectly aligned for efficient processing.

Key steps include:

● Feeding: Bottles enter the machine, often in random order.

● Sorting: The machine separates bottles based on size, shape, or orientation.

● Orienting: Bottles are turned or aligned to the correct position.

● Output: Bottles exit in a neat, organized stream ready for packaging.

Bottle unscramblers come in various designs to meet different production needs:

● Rotary Bottle Unscramblers: Use a rotating disc with slots to guide bottles into position. Ideal for high-speed, high-volume lines. They handle bottles quickly and efficiently, making them popular in many industries.

● Linear Bottle Unscramblers: Move bottles along a straight path using rails and guides. These are simpler and easier to maintain. They work well with bottles of unusual shapes or sizes that may not fit rotary systems.

● Specialized Bottle Unscramblers: Custom-built for unique requirements, such as fragile glass bottles or oddly shaped containers. These machines offer tailored solutions for challenging packaging needs.

Each type has advantages depending on the production speed, bottle type, space constraints, and product specifications.

Tip: When choosing a bottle unscrambler, consider your product's shape and size first—this ensures smooth operation and minimizes jams on your packaging line.

High-speed bottle unscramblers dramatically boost production efficiency. They handle large volumes of bottles quickly, far beyond manual capabilities. By automating sorting and orientation, these machines keep the production line moving smoothly without pauses. This continuous flow reduces bottlenecks and increases throughput, allowing manufacturers to meet tight deadlines and higher demand. For example, a rotary unscrambler can process hundreds of bottles per minute, maintaining a steady pace that manual sorting cannot match.

These machines ensure each bottle is perfectly aligned and oriented, which is vital for downstream processes like filling, capping, and labeling. Misaligned bottles can cause jams or errors, leading to costly downtime and wasted products. High-speed unscramblers maintain consistent accuracy, reducing mistakes and improving overall product quality. This consistency also helps maintain brand reputation by ensuring every package looks professional and meets quality standards.

By automating the bottle sorting and orientation process, high-speed unscramblers reduce the need for manual labor. This shift allows workers to focus on more complex tasks, improving workforce productivity and job satisfaction. It also lowers the risk of repetitive strain injuries common in manual sorting jobs. Automation minimizes human error, creating a safer and more reliable packaging environment.

Modern high-speed bottle unscramblers handle a wide range of bottle shapes, sizes, and materials. This versatility makes them suitable for various industries, including food and beverage, pharmaceuticals, cosmetics, and household products. Manufacturers can switch between different products quickly without extensive machine adjustments. For instance, a pharmaceutical line can use the same unscrambler for vials and bottles, while a beverage company can process different container sizes seamlessly.

High-speed bottle unscramblers handle containers gently, crucial for preserving fragile items like glass bottles. Rough or abrupt movements can cause cracks, chips, or breakage, leading to product loss and safety risks. These machines use carefully designed guides and cushioned surfaces to minimize impact during sorting and orientation. By protecting container integrity, unscramblers reduce waste and maintain product safety, ensuring customers receive flawless goods.

Proper bottle orientation directly affects filling accuracy. When bottles are correctly aligned and stable, filling machines can dispense precise volumes without spillage or overflow. Misaligned bottles risk underfilling or overfilling, which harms product consistency and increases waste. High-speed unscramblers guarantee uniform positioning, enabling filling equipment to operate at peak efficiency and maintain strict quality control standards. Accurate filling also supports compliance with regulatory requirements and boosts customer trust.

Beyond container safety, unscramblers help avoid damage to the product inside. Bottles jolted or tipped during unscrambling may spill or mix contents, especially in liquid or powder products. By maintaining steady, controlled handling, unscramblers reduce the chance of contamination or spoilage. This careful process safeguards product quality and shelf life. Additionally, minimizing damage lowers the risk of customer complaints, returns, and brand reputation harm.

Bottlenecks slow down the entire packaging line, causing delays and lost productivity. High-speed bottle unscramblers prevent these by ensuring bottles enter the production line in a smooth, steady stream. They organize bottles quickly, so downstream machines never starve for input. This steady flow keeps every step moving at its best pace. Without an unscrambler, bottles arrive randomly, causing jams or pauses. By sorting and aligning bottles before they reach filling or labeling stations, unscramblers eliminate these risks. This continuous flow is essential for meeting production targets and avoiding costly downtime.

Downtime happens when machines stop, often due to jams or misfeeds. Bottle unscramblers reduce these stoppages by feeding bottles correctly and consistently. They minimize human error, which often causes blockages. When bottles are correctly oriented and spaced, filling and capping machines run without interruptions. This reliability means fewer emergency stops and less time spent fixing issues. Also, unscramblers reduce wear on other machines by preventing erratic bottle movement. This leads to longer machine life and fewer repairs. In a high-speed line, even a few seconds of downtime can add up to significant losses. Unscramblers help keep lines running smoothly, maximizing uptime.

Automating bottle sorting and feeding frees workers from repetitive, tiring tasks. Instead, operators can focus on monitoring the line, quality control, or maintenance. This shift boosts overall productivity and job satisfaction. It also reduces the risk of injuries caused by manual bottle handling. Labor optimization means fewer staff needed for the same output, lowering labor costs. Plus, automation reduces human errors that cause delays or waste. Workers can be retrained for higher-value roles, improving workforce skills. A well-integrated unscrambler simplifies the entire packaging process, making it easier for staff to manage and troubleshoot the line.

High-speed bottle unscramblers significantly cut labor costs by automating the sorting and feeding process. Instead of relying on workers to manually pick, orient, and place bottles, these machines handle the task continuously and flawlessly. This reduces the number of staff needed on the packaging line, freeing employees to focus on more complex or supervisory roles. Automation also lowers the risk of repetitive strain injuries common in manual bottle handling jobs. Over time, labor savings add up, making unscramblers a smart investment for businesses aiming to optimize their workforce and reduce overhead.

Bottle unscramblers help minimize waste in several ways. First, by handling bottles gently and precisely, they reduce breakage and damage, especially for fragile glass containers. Fewer broken bottles mean less product loss and lower disposal costs. Second, proper bottle orientation ensures accurate filling and capping, preventing overfills, spills, or contamination. This accuracy reduces product waste and maintains consistent quality. By cutting down on errors and rejects, unscramblers help manufacturers save money and meet sustainability goals by reducing material waste.

Consistent bottle feeding from unscramblers protects downstream equipment like fillers, cappers, and labelers. When bottles arrive aligned and spaced correctly, machines operate smoothly without strain or jams. This steady flow prevents sudden stops and starts that cause wear and tear. Reduced mechanical stress leads to fewer breakdowns and extends equipment lifespan. Maintenance costs drop, and production uptime improves. Investing in a reliable bottle unscrambler can protect costly packaging machinery, saving money on repairs and replacements over the long term.

Selecting the ideal bottle unscrambler is crucial for smooth packaging operations. Several factors influence this choice, ensuring the machine fits your production needs perfectly.

The speed and scale of your production line determine the type of unscrambler you need. High-volume operations require machines capable of processing hundreds of bottles per minute without faltering. For example, rotary unscramblers excel in fast-paced environments due to their continuous rotation and rapid sorting capabilities. Smaller or medium-sized lines might benefit from linear unscramblers, which can handle moderate speeds with simpler mechanics. Matching the unscrambler’s capacity to your production volume prevents bottlenecks and maximizes throughput.

Bottle size, shape, and material impact the choice of unscrambler. Fragile glass bottles need gentle handling features, such as cushioned guides, to prevent damage. Bottles with unusual shapes or varying sizes might require specialized or adjustable unscramblers that can adapt quickly. For instance, if your line switches between tall, narrow bottles and short, wide ones, an unscrambler with quick changeover settings is ideal. Understanding your product’s physical traits ensures the unscrambler aligns bottles correctly, reducing jams and improving downstream processes.

Facility layout and available floor space are key practical considerations. Rotary unscramblers generally need more room due to their circular design, so they suit larger production areas. Linear unscramblers have a smaller footprint and fit well in tight spaces or narrow lines. Measuring your available space and planning the packaging line flow helps avoid costly rearrangements. Sometimes, compact unscramblers with vertical orientation can save space without sacrificing performance.

Your new unscrambler must work seamlessly with current machinery. Compatibility with fillers, cappers, and labelers ensures a smooth transition of bottles through each stage. Consider the conveyor height, speed synchronization, and control system compatibility. Some unscramblers offer customizable interfaces or modular designs to fit various line configurations. Proper integration reduces setup time, minimizes errors, and keeps the entire packaging line efficient.

In the food and beverage sector, high-speed bottle unscramblers play a vital role. They handle bottles, cans, and containers efficiently, ensuring smooth flow through filling and capping machines. These unscramblers accommodate various bottle sizes and shapes, from soda bottles to juice containers. Their fast operation helps meet high production demands, especially during peak seasons. By correctly orienting bottles, they reduce errors like spills or mislabeling, maintaining product quality and safety. For example, a beverage plant can process hundreds of bottles per minute, reducing downtime and boosting output.

Pharmaceutical manufacturing demands precision and care. Bottle unscramblers here handle delicate vials, ampoules, and bottles without causing damage. They ensure each container is correctly oriented for accurate filling and sealing, critical for dosage consistency and patient safety. These machines support strict regulatory compliance by minimizing contamination risks. Their gentle handling features protect fragile glass containers, reducing breakage and product loss. In fast-paced pharmaceutical lines, unscramblers maintain steady throughput, helping companies meet strict production schedules while preserving product integrity.

Cosmetic packaging lines benefit greatly from high-speed bottle unscramblers. These machines manage a variety of container types, including small bottles, jars, and tubes. They ensure consistent orientation, which is essential for precise filling, labeling, and capping. This consistency enhances the product’s aesthetic appeal, an important factor in consumer choice. Unscramblers also allow quick changeovers between different product lines, supporting the frequent variety in cosmetics manufacturing. By automating bottle handling, they reduce manual labor and improve line efficiency, helping brands maintain high standards and meet market demands.

Household product manufacturers use bottle unscramblers to handle containers such as spray bottles, detergent jugs, and cleaning solution bottles. These unscramblers sort and orient bottles efficiently, preparing them for filling and packaging. Their versatility enables handling of various shapes and sizes, from large detergent bottles to small spray containers. Automation reduces labor costs and speeds up production, helping companies keep pace with consumer demand. Gentle handling minimizes container damage, ensuring products reach customers in perfect condition. This reliability supports brand reputation and customer satisfaction.

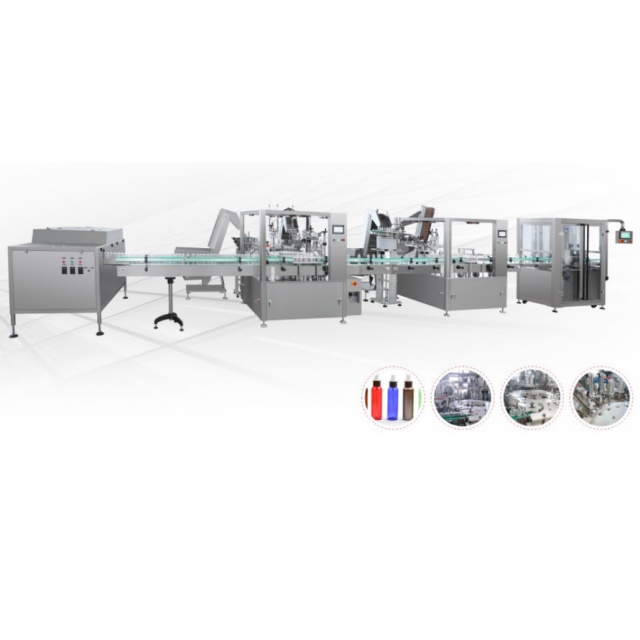

High-speed bottle unscramblers enhance efficiency by automating sorting, reducing labor, and minimizing waste. Their versatility across industries ensures consistent product quality and optimized packaging processes. As technology advances, bottle unscramblers will continue to evolve, offering even greater precision and adaptability. Wenzhou Zungwan Intelligent Machine Co.,Ltd. offers cutting-edge unscramblers that provide exceptional value, tailored to meet diverse production needs, ensuring seamless integration and improved productivity.

A: A Bottle Unscrambler organizes bottles arriving randomly and prepares them for packaging, ensuring smooth production flow.

A: By automating sorting and orientation, a Bottle Unscrambler reduces bottlenecks and increases throughput, boosting production efficiency.

A: High-speed Bottle Unscramblers handle large volumes quickly, maintaining accuracy and reducing manual labor, thus optimizing productivity.

A: The cost depends on production volume, bottle specifications, space constraints, and integration with existing equipment.