Wenzhou Zungwan - Packaging Machinery Equipment Manufacturers

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-29 Origin: Site

Ever wondered how bottles are sorted efficiently in massive production lines? The answer lies in bottle unscramblers, crucial machines in packaging. These devices transform chaotic bottle arrangements into orderly, upright positions, essential for seamless filling and labeling. In this post, you'll learn what bottle unscramblers are and their vital role in enhancing packaging efficiency and accuracy.

A bottle unscrambler is a specialized machine designed to sort and orient bottles automatically. It takes bottles arriving in a random, jumbled state and organizes them into a uniform, upright position. This ensures the bottles are ready for downstream processes like filling, capping, or labeling. Essentially, the unscrambler transforms disorder into order, streamlining the packaging line.

The functionality of a bottle unscrambler revolves around automation. Instead of relying on manual labor to sort and place bottles, the machine handles this task quickly and consistently. This reduces errors, prevents bottlenecks, and boosts overall production speed. The machine can handle various bottle shapes and sizes, adapting to different packaging needs.

Bottle unscramblers operate through a sequence of stages that manage feeding, sorting, and output:

● Feeding Stage: Bottles are loaded into the unscrambler, often in bulk. The machine accepts them from a hopper or conveyor belt, preparing them for sorting.

● Sorting and Orientation: This is the core of the unscrambler's work. Depending on the type, the machine uses rotating discs, rails, or guides to position bottles correctly. For example, rotary unscramblers spin a disc with pockets that catch bottles and turn them upright. Linear unscramblers guide bottles along a straight path, aligning them via rails or mechanical arms.

● Output Stage: Once bottles are sorted and oriented, they move out of the unscrambler onto the next conveyor or machine. At this point, bottles are uniformly aligned and ready for filling or labeling.

The entire process happens rapidly and continuously, allowing high-speed production lines to maintain a steady flow without interruption. Sensors and controls often monitor the process, adjusting speeds or handling jams automatically to keep operations smooth.

By automating the sorting and orientation process, bottle unscramblers reduce the need for manual intervention, lower labor costs, and minimize the risk of damage or errors. This makes them indispensable in modern packaging facilities.

Note: When selecting a bottle unscrambler, ensure it matches your bottle size and production speed needs, as machine mechanisms vary in handling different shapes and volumes.

Bottle unscramblers bring several important advantages to packaging lines. These machines automate the tedious task of sorting and orienting bottles, which results in major improvements across efficiency, accuracy, labor, and workflow.

One of the biggest benefits is a significant boost in efficiency. Bottle unscramblers handle large volumes of bottles quickly, far faster than manual sorting. This speed helps production lines run smoothly without bottlenecks or delays. It means manufacturers can meet higher demand and increase output without adding shifts or workers.

Bottle unscramblers ensure every bottle is oriented perfectly and uniformly. This precision reduces jams, spills, or damage during filling, capping, or labeling. Consistent orientation also maintains product quality and reduces waste caused by misaligned bottles. Automated sorting removes the variability human operators might introduce.

Sorting bottles by hand is time-consuming and physically demanding. Unscramblers replace this manual work, freeing employees to focus on more skilled tasks. This shift reduces labor costs and lowers the risk of repetitive strain injuries. It also minimizes errors caused by fatigue or distraction.

Integrating bottle unscramblers into production lines creates a seamless, automated workflow. The machines synchronize bottle orientation with upstream and downstream equipment, reducing downtime. This automation helps maintain a steady pace, improving overall line efficiency and reducing the need for human intervention.

Bottle unscramblers come in various designs, each tailored to meet different packaging needs. Choosing the right type depends on factors like production speed, bottle shape, and available space. Here’s a closer look at the main types:

Rotary unscramblers are the most common type. They use a spinning disc with pockets or slots that catch bottles randomly fed into the machine. As the disc rotates, it orients bottles upright and moves them to the next stage. This design suits high-speed production lines because it can handle large volumes quickly and continuously.

Rotary unscramblers excel at sorting standard-shaped bottles like round or cylindrical containers. Their circular motion allows smooth handling and minimal bottle damage. However, they often require more floor space due to their round footprint.

Linear unscramblers move bottles along a straight path rather than a circular one. Bottles enter the machine and are guided by rails or conveyor belts that align and orient them as they travel forward. This type is simpler and easier to maintain than rotary unscramblers.

Linear unscramblers work well for bottles with unusual shapes or sizes that might not fit into rotary pockets. They also fit better in tight spaces due to their straight-line design. However, they may operate at slower speeds compared to rotary models, making them ideal for medium-volume production lines.

Some packaging operations require customized unscramblers designed for specific bottle types or materials. These specialized machines handle delicate, irregular, or uniquely shaped bottles that standard unscramblers can’t process efficiently.

Specialized unscramblers often combine features from rotary and linear designs or include custom guides, sensors, and handling mechanisms. They can be tailored to fragile glass bottles, multi-chamber containers, or oddly shaped cosmetic bottles. Though they may cost more upfront, specialized unscramblers improve accuracy and reduce damage for challenging products.

The bottle sorting process starts at the feeding stage. Here, bottles arrive in bulk, often in a random jumble. The machine receives them through a hopper or conveyor belt. This stage focuses on moving bottles smoothly into the unscrambler without causing jams or damage. The feeding system must handle varying bottle sizes and shapes while maintaining a steady flow. Proper feeding ensures the machine can work continuously and efficiently.

Sorting and orientation form the heart of the bottle unscrambler’s operation. Once bottles enter the machine, they need to be positioned upright and aligned correctly. Depending on the machine type, this happens in different ways:

● Rotary Unscramblers use spinning discs with slots or pockets. Bottles drop into these pockets and are turned upright as the disc rotates. This method is fast and handles high volumes well.

● Linear Unscramblers guide bottles along straight rails or conveyor belts. Mechanical arms or guides nudge bottles into the proper orientation. This works well for oddly shaped or fragile bottles.

Sensors often monitor the bottles during this stage. They detect jams or misalignments and trigger adjustments or pauses to prevent errors. The goal is to have every bottle uniformly oriented, ready for the next step.

After sorting, bottles move to the output stage. Here, they transfer onto a conveyor or directly into filling or labeling machines. At this point, bottles are all facing the right way and spaced evenly. The output stage ensures a smooth handoff to downstream equipment, maintaining line speed and reducing downtime.

This stage may include additional checks or sensors to confirm bottle orientation. If any bottles are out of place, the system can reject or reroute them to avoid disruptions.

Selecting the right bottle unscrambler is key to optimizing your packaging line. Several factors influence this choice, ensuring your machine matches your production needs and space.

First, consider your production speed. High-speed lines need unscramblers that handle large volumes quickly without jams. Rotary unscramblers excel here, thanks to their spinning disc design that sorts bottles rapidly. For medium-speed lines, linear unscramblers may suffice, offering simpler mechanics but slightly slower throughput. Matching machine speed to your line prevents bottlenecks and keeps production smooth.

Next, assess your bottle types and sizes. Round, standard bottles fit well in rotary unscramblers, which use pockets to orient them. Oddly shaped or fragile bottles might require linear or specialized unscramblers, which guide bottles carefully along rails or use custom features. If your line handles multiple bottle sizes or shapes, look for machines with quick changeover capabilities or adjustable guides to maintain flexibility.

Your facility’s layout also matters. Rotary unscramblers need more floor space due to their circular footprint. Linear unscramblers have a slimmer, straight-line design, fitting better in tight or narrow areas. Evaluate your available space and how the unscrambler will integrate with existing conveyors or machines. Compact designs help optimize workflow in smaller facilities.

Finally, consider customization. Some operations require machines tailored to unique bottles or specific production challenges. Custom unscramblers can include special sensors, delicate handling features, or integration with other equipment. Though these may cost more upfront, they often improve efficiency and reduce product damage, offering long-term savings.

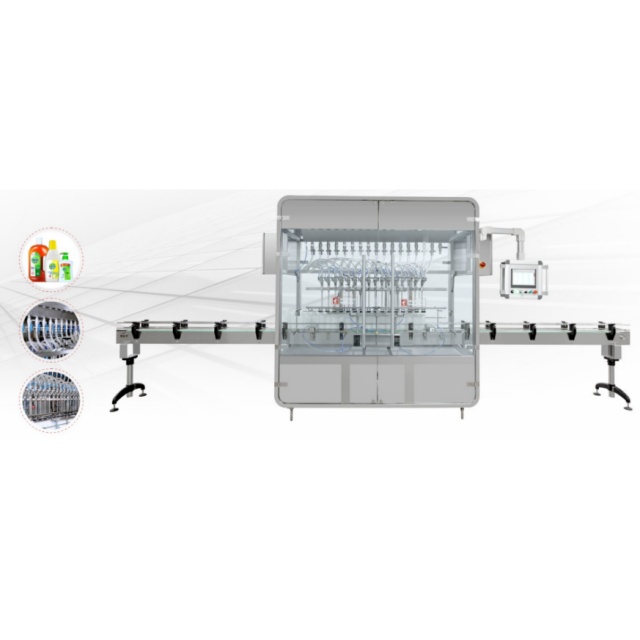

Bottle unscramblers streamline packaging by automating bottle sorting, enhancing efficiency, accuracy, and workflow. They reduce manual labor and improve consistency. The future of bottle unscramblers in packaging looks promising, with advancements expected to further optimize production lines. Companies like Wenzhou Zungwan Intelligent Machine Co.,Ltd. offer innovative unscrambling solutions. Their machines provide unique benefits, such as high-speed operation and versatile design, ensuring value and reliability for packaging facilities.

A: A Bottle Unscrambler is a machine that automatically sorts and orients bottles into a uniform, upright position, preparing them for filling, capping, or labeling processes.

A: Bottle Unscramblers enhance efficiency by quickly handling large volumes of bottles, reducing manual labor, and minimizing errors, thus preventing production bottlenecks.

A: Bottle Unscramblers are crucial for maintaining consistent bottle orientation, reducing labor costs, and ensuring smooth, automated production workflows.

A: The cost of Bottle Unscramblers varies based on type, customization, and production speed requirements, with specialized models typically being more expensive.

A: Rotary unscramblers use spinning discs for high-speed sorting, while linear unscramblers guide bottles along a straight path, suitable for unique shapes.