We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for aluminium tube filling and sealing machine supplier,

1000ml Bottle filling line supplier, penicillin bottle filling sealing machine supplier, bottle filling capping and labeling machine manufacturer, ointment tube filling and sealing machine manufacturer, nail polish filling and capping machine factory, Our tenet is "Reasonable prices, efficient production time and best service" We hope to cooperate with more customers for mutual development and benefits., Karachi, With the highest standards of product quality and service, our products have been exported to more than 25 countries like the USA, CANADA, GERMANY, FRANCE, UAE, Malaysia and so on.We are very pleased to serve customers from all over the world! We know that Labeling Machine brings great convenience to our production and life, so what are the working principles an

Wenzhou Zungwan Intelligent Machine Co.,Ltd. is the professional equipment manufacturer to keep researching and developi

Wenzhou Zungwan Intelligent Machine Co.,Ltd. is the professional equipment manufacturer to keep researching and developi

Tube Filling machine And Sealing machine is suitable for filling all kinds of paste and high viscosity fluids, suitable

Tube Filling machine And Sealing machine adopt the latest module circuit, stable working performance, high efficiency, a

Capping Machine is filling equipment specially designed for new oral liquid easy-pull bottles. The design is reasonable,

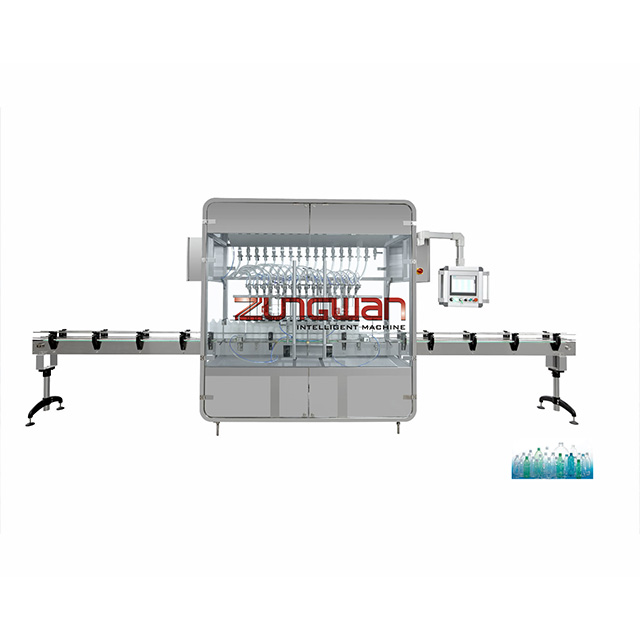

Liquid Filling Machine is used in the beverage, drinking water, and liquor industries and has become a very important eq

Wenzhou Zungwan Intelligent Machine Co.,Ltd. is the professional equipment manufacturer to keep researching and developi

Glass Bottle Filling Machine Granule Filling Machine Hazelnut Butter Filling Machine Honey Filling Machine Jam Filling Machine Ketchup Filling Machine Lemon Sauce Filling Machine …

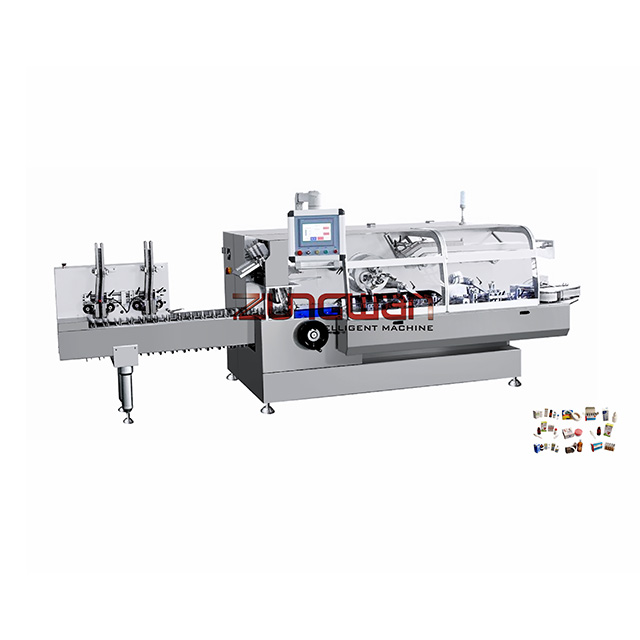

Cartoning machines have various functions of cycle stop flap closing, rotary cartons, rotary flap tuckers, and adjustable carton plows. As a leading cartoner machine manufacturer, BW …

Buy Perfume Capping Machine from Machine Business Opportunities, Perfume Capping Machine specifications: Perfume cap pressing machine

RGF 14-12-5 Full Automatic Bottling Machine Juice Filling Machine Price Juice Bottling Plant

This fertilizer bagging machine is composed of stock bin, feeding system, weigh hopper, bag clamp mechanism, frame, sensor, control cabinet, conveyor and sewing system. These can be divided into weighing part, discharging part and …

Buy lip gloss filling machine at an affordable price. This is an empty lip gloss filling machine. ... Big Mouth Lip Oil Private Label Transparent Plant Moisturizing Lip Gloss Wholesale Small Batch Order No Logo 2 Colors . US

Shampoo, coffee, shaving cream Contact parts are manufactured of stainless steel. It can …

Full Automatic Food Carton Box Packing Machine Production Line Manufacturers FOB Price: US