Persisting in "High high quality, Prompt Delivery, Aggressive Price", we've established long-term cooperation with clients from the two overseas and domestically and get new and old clients' superior comments for cosmetics labeling machine,

fertilizer sachet packing machine supplier, ZHGP-1928X Weight filling machine factory, Antibiotic glass bottle filling stoppering and capping machine wholesale, filling machine factory, ZHF-60Z Metal Tube Filling and Sealing Machine supplier, Base on the business concept of Quality first, we would like to meet more and more friends in the word and we hope provide the best product and service to you., Czech Republic, Make the women more attractive is our sales philosophy. "Being customers' trusted and preferred brand supplier" is the goal of our company. We've been strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future. Speaking of Bag packaging machines for large machinery, it is necessary to briefly talk about the knowledge of stand-up

The Mid-Autumn Festival is the second most important festival for a family reunion in China after the Spring Festival. B

Due to the particularity of the environment in which the Liquid Filling Machine equipment is used, the structure of the

In our production and life, the unscrambler has an important influence on us. So what are the types of Bottle Unscramble

Liquid Filling Machine is a kind of process machinery, its process characteristics are more obvious, for the design requ

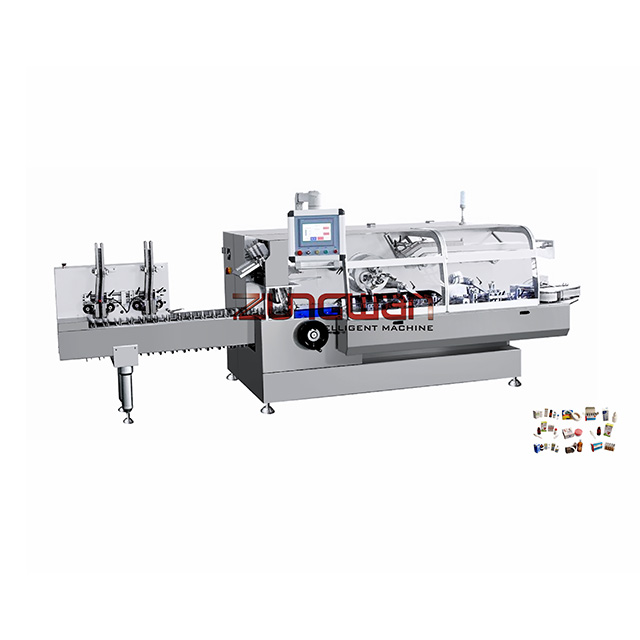

Wenzhou Zungwan Intelligent Machine Co.,Ltd. is the professional equipment manufacturer to keep researching and developi

Wenzhou Zungwan Intelligent Machine Co.,Ltd. is the professional equipment manufacturer to keep researching and developi

With the increasingly fierce competition in the manufacturing and production of plastic bottles in the food and pharmace

Popular Products of CAPPING LIPSTICK CAPPING MACHINE by Filling and Capping Machine - ynb limited from China. ... Cap

Plugging quality is monitored with MVS (machine vision system),to ensure higher acceptability (Option). Process parameters can be timely printed,stored and retrievable. All contact parts are of SUS 316L and medical silicon rubber . Machine is coated with SUS 304 and 6061 oxidated aluminum alloy. Technical Specifications

Description Hand Washing Filling Machine 8 heads Piston Filling Machine ( Servo ) with pump Brief Introduction ? Contact part material : SS 316 , other machine parts : SS 304 ? Suitable material: Oil, jams, daily chemicals, and something that very viscous.

China Metal Screw Cap Capping Machine manufacturers - Select 2022 high quality Metal …

3-in-1 Mineral Water Filling Capping Machine 12000BPH 1. CGF24-24-8 Water bottling machine is 12,000BPH 2. Automatic Washing Filling Capping Machine (3-in-1) 3. SS304 stainless steel 4. SIEMENS programmed controller (PLC) 5. ISO9001, CE, SGS, BV, SONCAP Quantity: Inquire Model: CGF24-24-8 12000B/H Brand: KING MACHINE Product Description

High Accuracy Plastic Tube Filling Machine Tube Length 50-253mm PLC ControlContact Now. …

Semi-Auto Linear Type High Speed Mascara Filling Machine Application for Mascara Filling Machine This machine is widely used for filling mascara, lip oil, eye-liner products. It can work …

Intellectual High-viscosity Filler. Intellectual High-viscosity Filler,Variable speed filling: In the filling process, when close to the target filling volume to achieve a slow speed can be applied when …