We pursue the administration tenet of "Quality is remarkable, Services is supreme, Status is first", and will sincerely create and share success with all customers for Automatic filling and pump capping machine supplier,

potato chips Packing Machine factory, hand wash liquid filling machine factory, Troubleshooting of cartoning machine factory, Nasal Spray Filling And Capping Machine, Pump Capper supplier, We welcome buyers, business enterprise associations and good friends from all sections in the planet to get hold of us and request cooperation for mutual gains., The Swiss, Taking the core concept of "to be the Responsible". We'll redound up on society for high quality merchandise and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world. Liquid Filling Machine is specially designed for filling easy-to-open bottles. It has a reasonable design, simple struct

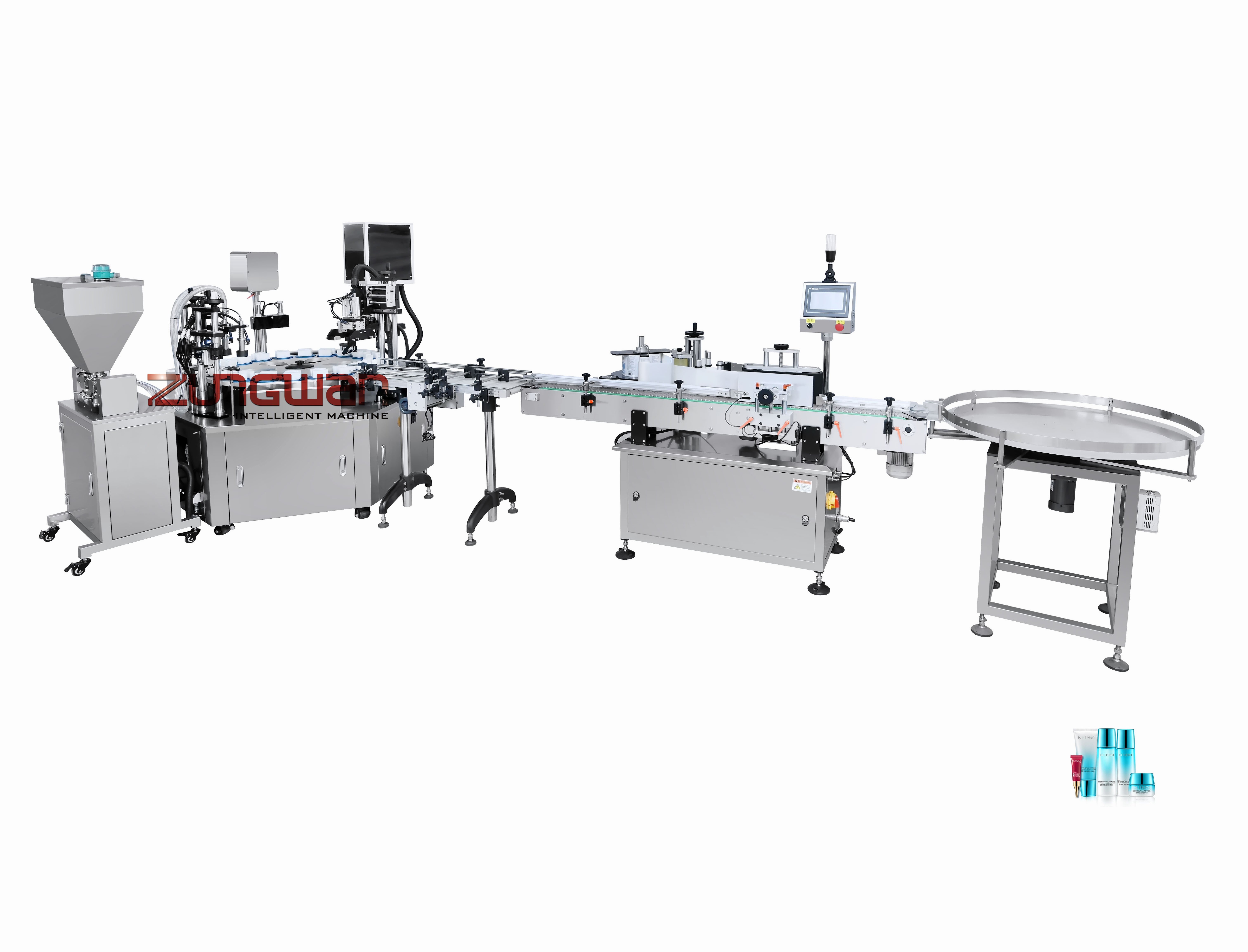

Cosmetic Filling Machine And Capping machine is very simple and convenient in operation, accuracy error, installation ad

There is already a lot of knowledge about the Labeling Machine in the market, but the Labeling Machine will appear crook

As people are enjoying life more and more now, most of the manual labor has been replaced. It is machine consumption. Me

Wenzhou Zungwan Intelligent Machine Co.,Ltd. is the professional equipment manufacturer to keep researching and developi

How to choose a Cosmetic Filling machine And Capping machine?Nowadays, the number and types of Cosmetic Filling machines

The Mid-Autumn Festival is the second most important festival for a family reunion in China after the Spring Festival. B

Tube Filling machine And Sealing machine is suitable for filling all kinds of paste and high viscosity fluids, suitable

We are one of the leading manufacturers and suppliers of Semi Automatic Filling Machines with Bench Model. Description / Specification Mechanical no electricity required. Filling range 250 ml to 5 Ltrs. Attachment for 100ml filling …

Delivering an efficient, personal service that is built around your specific custom requirements in liquid filling machines to suit your production and marketing objectives. For detailed information, contact our Sales Director Marco Solferini …

Automatic Grade: Automatic Driven Type: Electric Voltage: 220/380V;50/60HZ Power: 1.5kw …

Manufacturer of Weighmetric Filling Machine - Intelligent Weighing Filling Machine offered by Sahithi Pack Package System, Secunderabad, Telangana. X. Sahithi Pack Package System. Secunderabad, Hyderabad, Telangana

Following Capping Machine The following capping machine consists of the cap unscrambler, …

An empty videos list! View all videos; Menu

This website should be used for information purposes only by patients who are tube feeding, their carers or parents. The information provided does not replace the advice and supervision of a doctor, dietitian or any other member of the healthcare team.