We are a professional manufacturer with integrated R&D, production & sales and aftersales service. Cream Filling And Capping Machine factory,

toothpaste tube filler and sealer, Duck Mouth Capper, syringes filling and closing machine, ZHF-80Z Metal Tube Filling and Sealing Machine supplier, Tube code printing Machine factory, Never-ending improvement and striving for 0% deficiency are our two main quality policies. Should you need anything, don't hesitate to contact us., Somalia, we always keep our credit and mutual benefit to our client, insist our high quality service to moving our clients. always welcome the our friends and clients to come and visit our company and guid our business, if you are interested in our products, you can also submit your purchase information online, and we will contact you immediately, we keep our highly sincere cooperation and wish everything in your side are all well. Tube Filling machine And Sealing machine is advanced equipment for sealing plastic pipes and aluminum-plastic pipes. It

Now Bag Packing Machine is the most popular packaging equipment in the market, and it is used in all walks of life. Now

The Cosmetic Filling machine And Capping machine integrates the functions of air purification, filling, inserting, cappi

Bottle Unscrambler scientific maintenance and daily management institutionalization are very important. Scientific maint

Speaking of Bag packaging machines for large machinery, it is necessary to briefly talk about the knowledge of stand-up

Liquid Filling Machine is specially designed for filling easy-to-open bottles. It has a reasonable design, simple struct

Celebrate the 10th anniversary of ZUNGWAN intelligent machinery——A letter from central machinery to youHello, partners,

The Pharmaceutical Filler and Capper is no stranger to the health care industry, after all, it has a major impact on it.

Home ?Filling Machine Quick Details Brand Name: Kimyi Applicable Materials: High viscosity materials Machine Body: 304L stainless steel Filling Speed: 20-40 times / minute Working Pressure: 0.4MPA-0.6MPA Filling Range: 3-1000ML Filling Error: ± 0.1% Machine Weight: 55kgs Dimensions: 430x430x1500mm Payment

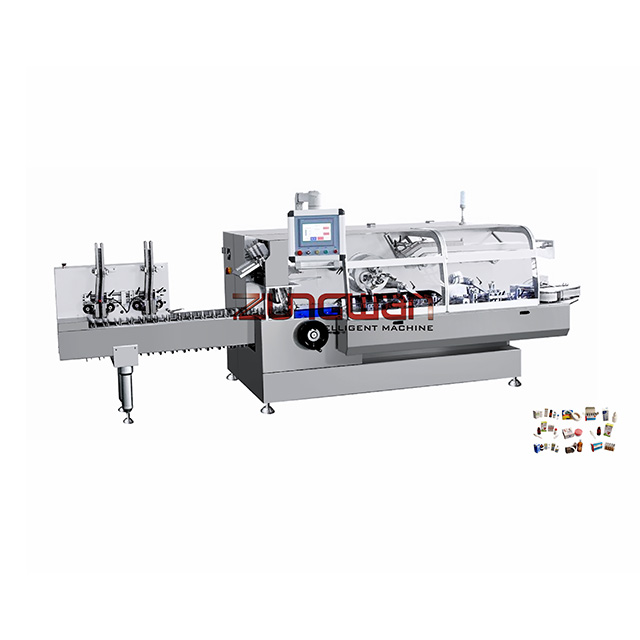

ELITER attaches importance to the versatility, performance, quality and cost of automatic cartoning machines and we try to make a ideal balance between them. Our automatic cartoning machines are designed with horizontal end-load pattern. The structure is of adjustable structure to fit a wide range of carton sizes regarless of their styles.

PLC Controlled Piston Filling Machine RNDGP—Z—6 Application of PLC Controlled Piston …

The toothpaste industry requires the accurate filling and high reliability that Norden provides by using the same field-proven technical solutions in all of our machines models to ensure accurate tube print orientation, filling and sealing. Contact UsSend Inquiry Toothpaste Tube Filling Machine …

Automatic Bottle Feeding Table Bottle/Automatic Bottle Feeding of Various Square Bottles FOB Price: US

Lipstick Heating Mixing Filling Machine /Cosmetic Manual lipstick making machine lip balm lip gloss heating filling machine

R100 Labeling Machines Automatic Label Rewinding Machine Thermal Adhesive Barcode Label Rewinder Good Quality Factory Price

High-tech pharmaceutical packaging systems The product navigator provides you with an overview of the series and machines available for your pharmaceutical application. On request, we will be pleased to examine the possibility of customized solutions, e.g. for similar packaging materials, specific process requirements, higher output etc. Containers