Wenzhou Zungwan Intelligent Machine Co.,Ltd. is the professional equipment manufacturer to keep researching and developi

With its extremely high-efficiency performance, the automatic Labeling machine attracts a strong demand of users. Effici

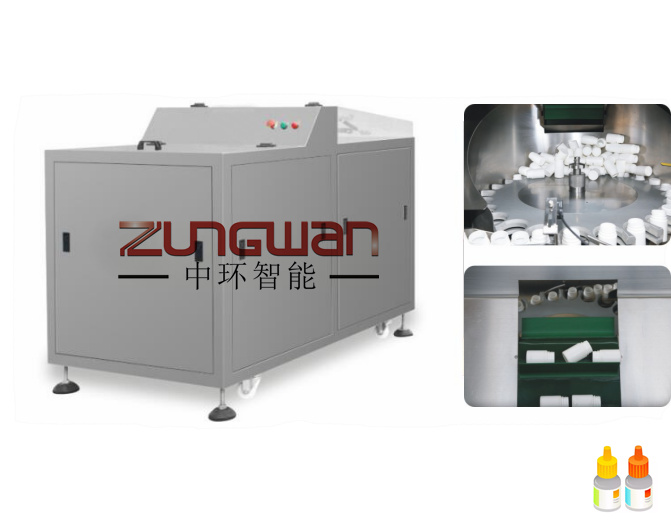

In our production and life, Capping Machine is also called a Capping Machine, Capping Machine, or Capping Machine, which

Wenzhou Zungwan Intelligent Machine Co.,Ltd. is the professional equipment manufacturer to keep researching and developi

Liquid Filling Machine is specially designed for filling easy-to-open bottles. It has a reasonable design, simple struct

With the increasingly fierce competition in the manufacturing and production of plastic bottles in the food and pharmace

After we purchase Pharmaceutical Filler and Capper, we need to install and debug Pharmaceutical Filler and Capper. Let's

Bag Packing Machine consists of vacuum pump, motor, vacuum chamber, sealing strip, plexiglass plate cover, airbag, solen

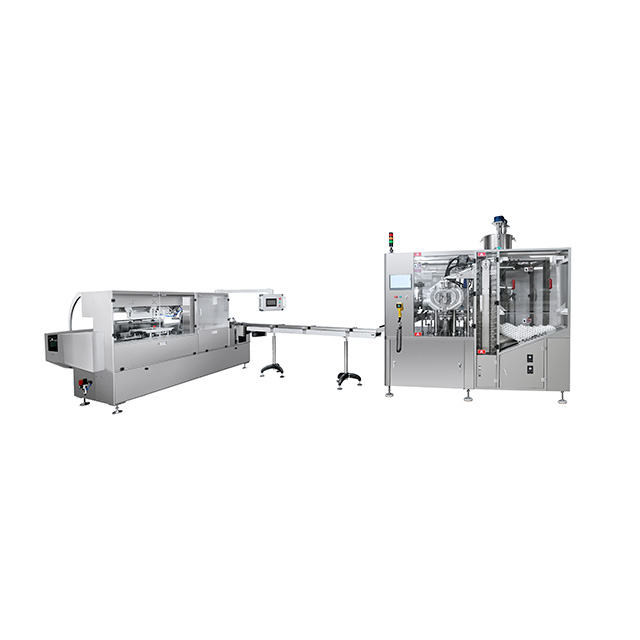

Automatic cartoning machine Cama Machine code: 708-388 Brand: Cama Automatic cartoning machine. Brand: Bed, Bed Group. Model: WRAP-AROUND FW749. Production: 90 packages per minute. Year 2007. Electronic packaging machine for packaging products such as bags, boxes, cups, flow-wraps and rigid containers... Automatic cartoning machine Bosch

Blister-cartoning-machine companies Find Blister-cartoning-machine manufacturers, suppliers, exporters, factories and trading agents Our factory has a capacity of 3000sets/year and all our products has CE certificate and we passed ISO9001. I will attach the ...

Eye-drop Bottle Filling Machine (Mac Tech Products) - . Eye-drop Bottle Filling Machine (Mac Tech Products) Automatic bottle filling capping machine Eyedrop 2-30ml vial small bottle filling and screw

Manufacturer/Factory; ISO 9001, ISO 9000, ISO 14001, ISO 14000, ISO 20000, OHSAS/ OHSMS 18001, IATF16949, HSE, ISO 14064, QC 080000, GMP, BSCI, BRC, SA 8000, QHSE ...

Filling Capping and Labeling Machine Total 55 Filling Capping and Labeling Machine Products 3 / 3 Video Automatic Desktop Oil Hand Sanitizer Bottle Liquid Soap Semi Automatic Filling Capping Labeling Machine FOB Price: US

Lip filler injection is a simple procedure performed at a doctor’s office with almost no downtime. …

Automatic Tube Filling and Pump Capping Machine DTNX-60XB Lip gloss filling machine ZHJM-1647M Replay Replay Recommended OEM Perfume Filling Capping Pressing Machine ZHS-80PM Manufacturer ...

The invention provides a finished product output device of a storage battery pack machine, and relates to the field of the production of storage batteries. When an existing finished product output device is installed, only one position is selectable between a conveyer ...