Speaking of Bag packaging machines for large machinery, it is necessary to briefly talk about the knowledge of stand-up

Cosmetic Filling Machine And Capping machine is very simple and convenient in operation, accuracy error, installation ad

Wenzhou Zungwan Intelligent Machine Co.,Ltd. is the professional equipment manufacturer to keep researching and developi

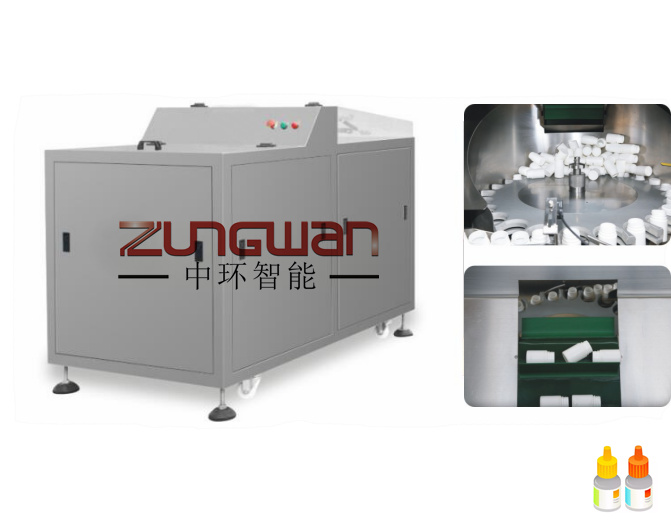

The Pharmaceutical Filler and Capper is no stranger to the health care industry, after all, it has a major impact on it.

Tube Filling machine And Sealing machine is suitable for filling all kinds of paste and high viscosity fluids, suitable

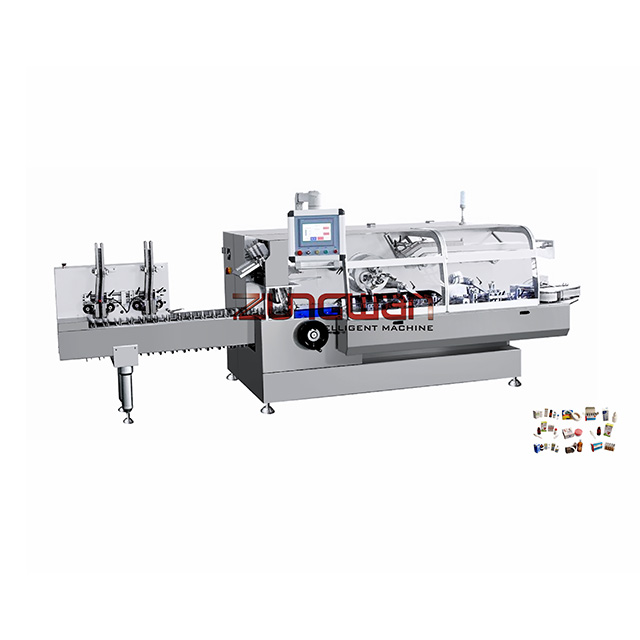

Cartoning machine is the description of automatic loading of medicine bottles, trays, ointments, etc. into folded carton

Pharmaceutical Filler and Capper, whether semi-automatic or fully automatic, will encounter more or less in the process

How to choose a Cosmetic Filling machine And Capping machine?Nowadays, the number and types of Cosmetic Filling machines

TECHNICAL SPECIFICATION: Model: SBTFS

Labelette’s APS-134 is an easy to operate Automatic Horizontal Wrap Labeler. The APS-134 is designed to label unwieldy round containers horizontally oriented with a full or partial wrap label such as pens, lip sticks, test tubes/ampules and other cylindrical containers. APS 206 The APS-206 is economical, self-contained and easy to operate.

Multi-function small sachets spice powder grain filling weight packing machine tea bag coffee …

Penicillin Vial/Bottle/Oral Liquid Bottles/Tubular Vial Liquid Filling and Sealing Machine Bottle charging, positioning, filling, and bottle discharging are all automatic, if the bottle is not on the right position, the bottle is blocked, or the filling pipe is not inserted into the bottle when filling, the equipment will protect automati

Spare Parts, Repair, Maintenance, Upgrade and Service for a King ISEC150 Bottle Press Capping Machine Display: 24 per page Sort by: Best selling View C.E.King Limited King ISEC150 Screw Capper Manual £50 Add to cart C.E. King Limited CP02556 - Cap Turnover £412.62 Add to cart C.E.King Limited King ISEC 150 60HZ Press Capper Diagram £30 Add to cart

These clear wholesale cosmetic bottles come in 15ML, 30ML, and 50ML. Eco-Friendly Collection Our Eco-Friendly collection includes recyclable wholesale plastic airless bottles and contains an airless dispensing pump engine made out of Polypropylene. Our sustainable cosmetic packaging bottles come in all sizes from 5 ML to 150 ML. Primal Collection

HighSpeedCappingMachine12 Automatic CappingMachine US

TF-100A Tube Filler - SaintyCo TF-100A Tube Filler. The TF-100 Tube Filling Machine can be used in for pharmaceuticals, food products, cosmetics and chemicals. Tube feeding, marking identification, filling, folding o... Home ?Filling Machinery ?100A Automatic Tube Filling And Sealing Machine Plastic Fast Easy Filler