We've got a specialist, effectiveness staff to supply high quality service for our shopper. We always follow the tenet of customer-oriented, details-focused for Automatic Bottle Capper manufacturer,

Perfume filling machine supplier, penicillin bottle filling machine supplier, liquid filling and capping machine factory, Pre-sterilized syringes filling plugging machine manufacturer, JF-A160 Bottle Unscrambler factory, Our ultimate target is usually to rank as a top brand also to lead as a pioneer in our field. We are sure our profitable experience in tool generation will gain customer's trust, Wish to co-operate and co-create a far better foreseeable future with you!, Burundi, Now we have a dedicated and aggressive sales team, and many branches, catering to our main customers. We have been looking for long-term business partnerships, and ensure our suppliers that they will undoubtedly benefit in both short and long run. The Mid-Autumn Festival is the second most important festival for a family reunion in China after the Spring Festival. B

The Tube Filling machine And Sealing machine, as its name implies, is a machine that can be filled and sealed. There are

Cartoning machine is the description of automatic loading of medicine bottles, trays, ointments, etc. into folded carton

Celebrate the 10th anniversary of ZUNGWAN intelligent machinery——A letter from central machinery to youHello, partners,

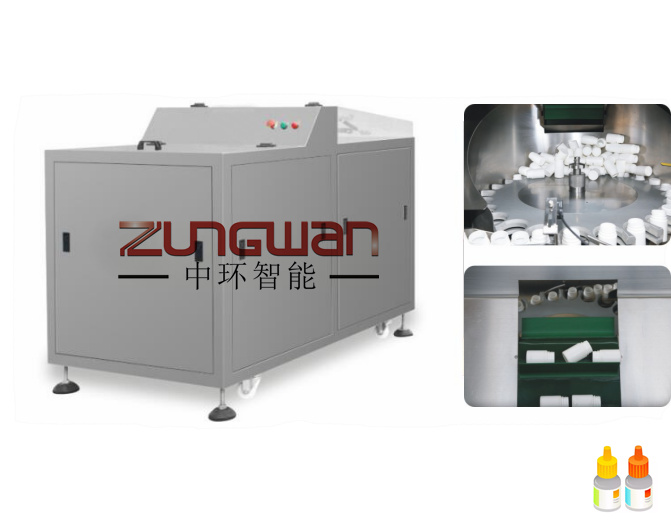

The Cosmetic Filling machine And Capping machine integrates the functions of air purification, filling, inserting, cappi

In our daily life, Capping Machine plays a vital role for us, so what are the main work processes and precautions of the

Cartoning Machine effectively guarantees the packing quality of items and the safe operation of the mechanismWe know tha

With its extremely high-efficiency performance, the automatic Labeling machine attracts a strong demand of users. Effici

Learn more about Accraply’s catalog of front and back labeling machines by following the links below. 35PW Labeling System 9000PW High Speed Labeling System Harland Mercury High Speed Labeler Harland Titan High Speed Labeler NEW! Sirius 100 Pressure Sensitive Labeling System NEW! Sirius MK6 Advanced Pharmaceutical Grade Labeler

King Machine offers oil filling solutions that are accurate, hygiene and no residual. KEY FEATURES OF WATER LINE Manufacturer can give you best price and reliable support on service and spare parts supply We employ 100 packaging scientists, engineers and designers Strict Assembly parts inspection and pre-shippment inspection

A-Frame guarding provides improved machine access while also making sure the that the operators have full visual compliance of the products and cartons while in operation. As a …

Machinery Packaging Machines Filling Machines Wholesale filling machine for …

Category:Preparation Equipment > Medicine Filling Machine; Product Name: ZHF-80Z Metal Tube Filling and Sealing Machine; Price(USD): 0.00. Get more product information on Pharmasources.

We manufacture Conveying Systems, Rotary Tables-Accumulation and unscrambling, Hugger Belt Transfer Conveyors, Hoppers, Powder, Liquid and other levels of Viscosity, Automatic Filling Machines , Capping and Labeling Machines or a fully integrated system, we have the experience to ensure your satisfaction. 2366 West 77th Street, Unit 2366 ...

Soft Tube Filling And Sealing Machine can fill different type of tubes including Cosmetic Creams, Pastes, Honey tube filling machine, Gel tube filling machine, Gum tube filling machine , Balms tube filling sealing machine , Ointments into the Lami / Plastic Tube. Add to cart. SKU: W9W6LZ37RT Category: Tube Filling Machines Tags: Soft, Tube.

Tru Earth Eco-Strips Laundry Detergent Strips - 64 Loads - Eco-Friendly, Biodegradable Packaging, Ultra-Concentrated, Pre-Measured Strips, Easy Storage - Great for Machine Washing - Lilac Breeze : Amazon.co.uk: Grocery