Our firm has been concentrating on brand strategy. Customers' satisfaction is our best advertising. We also offer OEM provider for Cream Filling And Capping Machine manufacturer,

Oil Filling and Corking machine supplier, Liquid Mosquito Repellent Filling machine manufacturer, Automatic Filling And Capping Machine factory, Mascara Filling & Plugging And Capping Machine wholesale, QLP-120 Automatic Bottling Machine, We also ensure that your selection will be crafted with the highest quality and reliability. Please feel free to contact us for further information., Dubai, As a well educated, innovative and energetic staff,we are responsible for all elements of the research, design, manufacturing, sales and distribution. With studying and developing new techniques,we are not only following but also leading the fashion industry. We listen attentively to the feedback from our customers and provide instant communication. You will instantly feel our expertise and attentive service. The Pharmaceutical Filler and Capper is no stranger to the health care industry, after all, it has a major impact on it.

Analysis of common failures of Cartooning MachineIn our production and life, the Cartoning Machine is of great significa

Speaking of Bag packaging machines for large machinery, it is necessary to briefly talk about the knowledge of stand-up

Now Bag Packing Machine is the most popular packaging equipment in the market, and it is used in all walks of life. Now

With the increasingly fierce competition in the manufacturing and production of plastic bottles in the food and pharmace

Liquid Filling Machine is a kind of process machinery, its process characteristics are more obvious, for the design requ

Cosmetic Filling Machine And Capping machine is very simple and convenient in operation, accuracy error, installation ad

After we purchase Pharmaceutical Filler and Capper, we need to install and debug Pharmaceutical Filler and Capper. Let's

The video is VFP PLC Controlled Filling Machine in youtube. Please kindly check nad thanks! Major characteristics : This machine is mainly applied in oil realm ,agrochemical and pharmaceuticals industries . It is especially designed for lube and edible oil . Easily controlled by computer (PLC), touch screen control panel .

China Tube Filler Manufacturer, Tube Filling, Tube Filling and Sealing Machine Supplier - Sainty Machinery Factory Home Manufacturers/Suppliers Inquiry Basket Sainty Machinery Factory Mr. Tony Manager Export Department Address: 402

Snacks Packing Machine Finopack snack packing machine manufacturer can provide …

Filling Volume 5-200ml Filling Capacity 30-80PCS/Min Filling Accuracy ≤±1% Power Supply 220V/380V,50/60Hz Trademark Ipanda Transport Package Wooden Box Specification 2500 (L)× 1000 (W)× 1700 (H)mm Origin Shanghai China Product Description Automatic Filling Plugging Capping Machine for Nasal Spray Technical Parameter Overview:

Add: NO. 11,Yuefeng Road, Zhangjiagang City, Jiangsu Province. China Tel: 0086-512-58587410 Fax: 0086-512-58587410 Email: info@utechmachine Mob: 0086-13962296786 ...

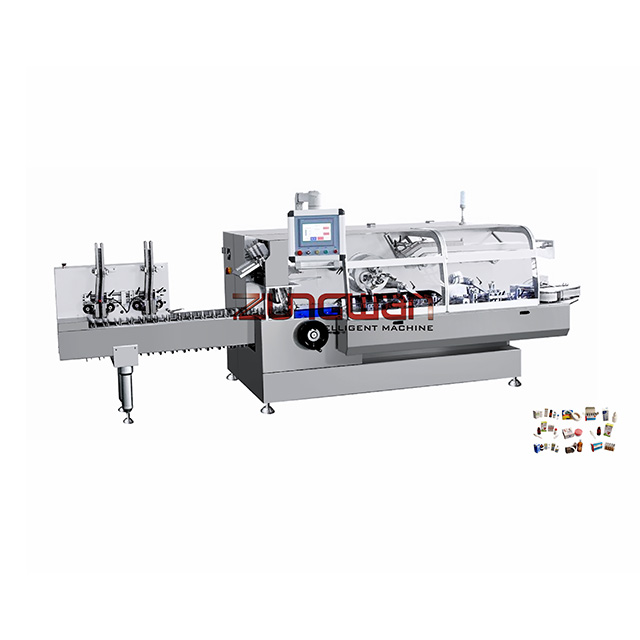

Zhejiang, China HS Code 8422303090 Production Capacity 30 Sets/Month Product Description Machine Description: KXZ-180B Automatic cartoning machine can pack products into carton box and seal the box automati

Automatic Refills Counting Machine Get Price Quote Application : Industrial Voltage : 220V, 380V Warranty : 2years Type : Refills Counting Machine Automatic Grade : Automatic Weight : 100-1000kg Your search for the best automatic more... 08047020182 Send Inquiry 12 Yrs Panchal Engineering Works Malad West, Mumbai, Maharashtra