Most Bag Packing Machines track and adjust various mechanical parameters through intelligent control instruments and men

After the Labeling machine sensor sends a signal that the labeling object is ready to be labeled, the drive wheel on the

Speaking of Bag packaging machines for large machinery, it is necessary to briefly talk about the knowledge of stand-up

Bag Packing Machine consists of vacuum pump, motor, vacuum chamber, sealing strip, plexiglass plate cover, airbag, solen

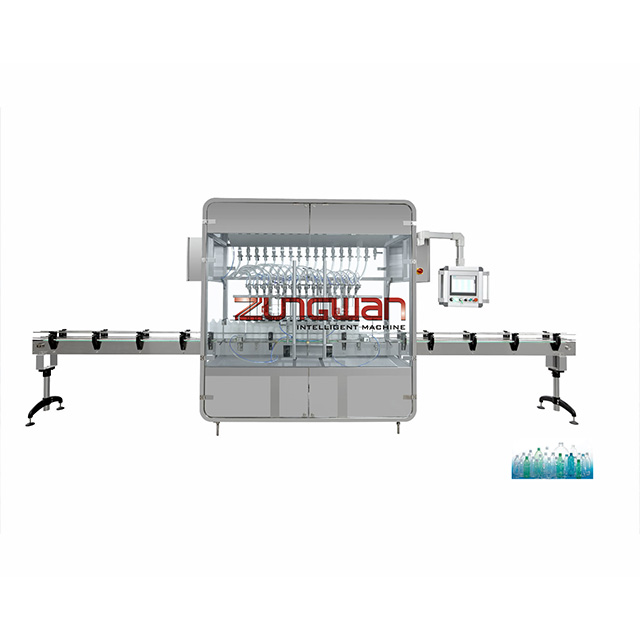

Wenzhou Zungwan Intelligent Machine Co.,Ltd. is the professional equipment manufacturer to keep researching and developi

In our production and life, the Liquid Filling Machine has a significant impact on many industries, so what is the metho

The Tube Filling machine And Sealing machine, as its name implies, is a machine that can be filled and sealed. There are

In our daily life, Capping Machine plays a vital role for us, so what are the main work processes and precautions of the

Double sided ( Front and Back) labelling machine for Lube Oil Jar bottle Send Enquiry See Our Clients View Catalog Suitable for applying Front, Back or Side Labels on Flat/Oval/Square/Round shape containers with output Up to 100 Labels per minute depending on …

Complete Automated Machine Using HMI, PLC, Encoder And PUMP Technology. No Change Part Required For Different Filling Grammage. All Part Comes In Contact With Cream Are Made Using SS 316L Which Include The Hopper, …

Capping Liquid Filling Machine Top Quality Automatic Capping Drug Oral Solution Liquid …

BLENZOR’s Fully Automatic Tube Filling Sealing Machine is ideal for all types of industrial mass production. Fully Automatic Tube Filling Sealing Machine is useful for wide range product packing application. The structure of Fully Automatic Tube Filling Sealing Machine is made from strong Stainless Steel fabrication base.

Auto Capper7,258products found from 201 Auto Capper manufacturers

Descriptions: Moskick Natural Liquid Mosquito Vaporizer made from Natural Ingredients. Additional Information: Item Code: LV-001 Production Capacity: 5000 Units/Day Delivery Time: Immediate Packaging Details: 100 Pieces 45ml/Carton Products

MY-SJ1000 Multi-Function Liquid Sachet Packaging Machine Bag Length: 50-150mm Packing film width: 100-320mm Packing capacity: 50-500ml Packing speed: 33-37bags/min Bag Width: 40-150mm Weight: 275kg Dimension: 880*760*1800mm Add to ...

Cosmetic Labeling Machine Assume full responsibility to meet all demands of our clients; …