We sincerely hope to establish long-term business relations of mutual benefit with you, and to become one of your most reliable China suppliers. automatic bottle washing filling and capping machine,

capping machine factory, Images for bottle filling line factory, leidex lipstick filling machine, PLC Controlled Piston Filling Machine supplier, pump cap capping machine, We warmly welcome your participation according to mutual rewards during the around long term., Rwanda, we've got all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner. The Pharmaceutical Filler and Capper is no stranger to the health care industry, after all, it has a major impact on it.

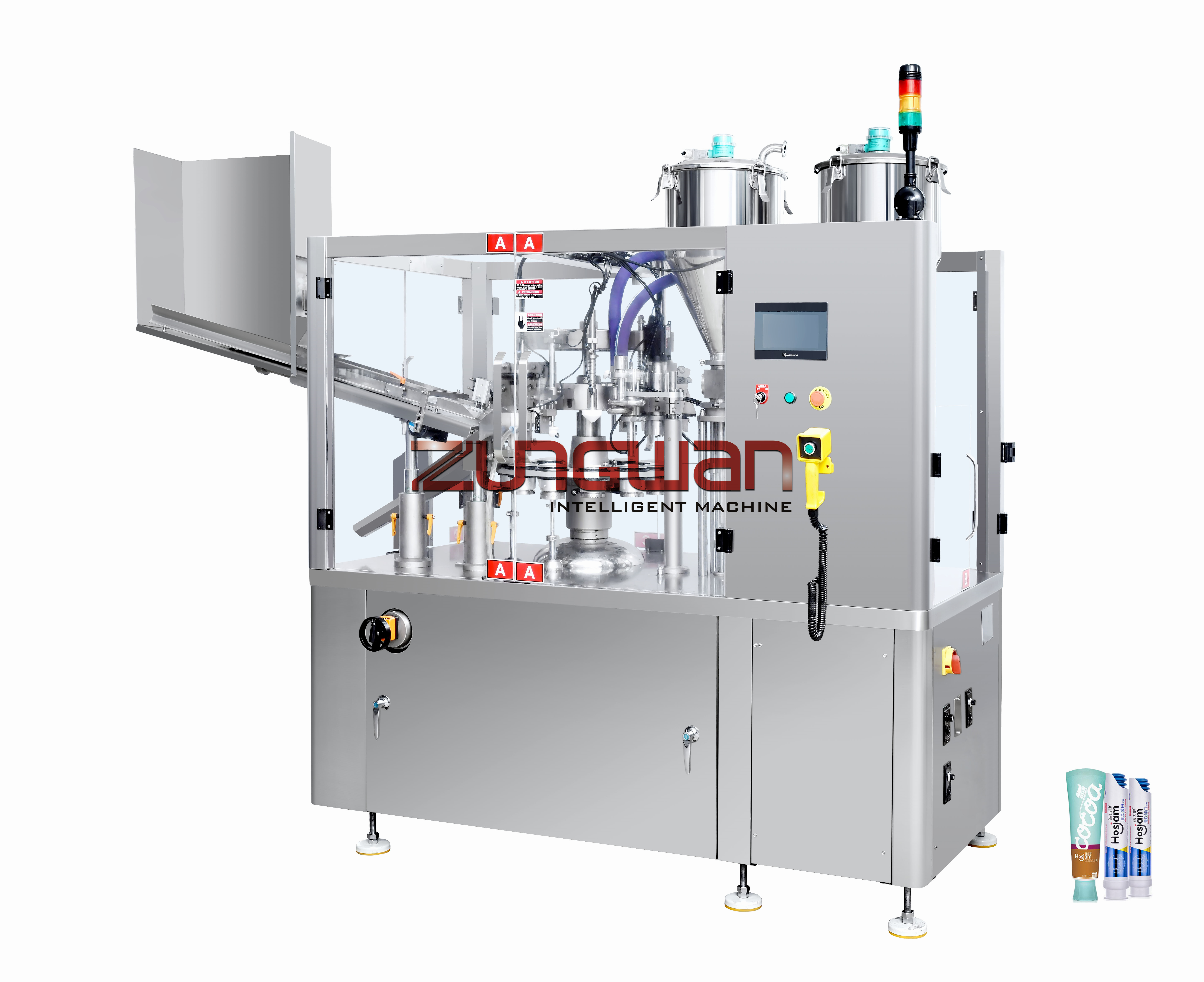

Cosmetic Filling Machine And Capping machine is very simple and convenient in operation, accuracy error, installation ad

The Mid-Autumn Festival is the second most important festival for a family reunion in China after the Spring Festival. B

Tube Filling machine And Sealing machine is suitable for filling all kinds of paste and high viscosity fluids, suitable

With the increasingly fierce competition in the manufacturing and production of plastic bottles in the food and pharmace

Liquid Filling Machine is used in the beverage, drinking water, and liquor industries and has become a very important eq

In our production and life, the unscrambler has an important influence on us. So what are the types of Bottle Unscramble

Due to the particularity of the environment in which the Liquid Filling Machine equipment is used, the structure of the

Cosmetic Jar Labeling Machine (3073 products available) 1 / 6 Horizontal Way Labeling …

Specialists in Liquid Filling Systems 866-258-1914 Filamatic provides the widest range of liquid filling capabilities and industry experience while delivering the lowest cost of ownership for our customers. We excel in delivering flexible, customized solutions for every stage of …

1. self-flow filling machine 2. Piston filling machine (Option 1: one servo motor to control all filling nozzles; Option 2: each filling head is controlled by each motor) 3. Flowmeter filling machine …

This series of manual liquid quantitative filling machine is specially designed for small filling output and low budget. Its structure is simpler and more reasonable, with higher accuracy and easier operation. It is well suitable for filling viscous kinds of liquid or viscous liquid in medicine, daily chemical, food, pesticide, and other ...

Common faults are: (1) bit control ring alarm: may be open measurement loop; The measuring system is damaged and the bit control unit is damaged internally. (2) no instruction on the movement, may be too high drift, positive feedback, position control unit failure; The measuring element is damaged.

Neostarpack is an industrial Semi-automatic Round Bottle Labeller

For packing of: Go to VMW Vertical form fill and seal machine R-600 The vertical form fill and seal machine for a bag width up to 600 mm. Suitable for extra thick films up to 800 μ. For packing of: Go to R-600 Continuous/intermittent vertical …

Four-Head Piston Oil Filling Machine Semi-automatic (4-head water filler, liquid bottling machine, water dosing machine),US