Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers' demands for Following type filling machines factory,

dish wash liquid filling machine supplier, Inline Filling Systems supplier, detergent powder bag packing machine, Automatic Bottle Capper wholesale, Pigment fine powder filling machine wholesale, It can be our wonderful honor to meet your requires.We sincerely hope we can cooperate along with you inside the around long term., Niger, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products and solutions have been exported to more than 15 countries in the world and have been widely used by customers. Analysis of common failures of Cartooning MachineIn our production and life, the Cartoning Machine is of great significa

There is already a lot of knowledge about the Labeling Machine in the market, but the Labeling Machine will appear crook

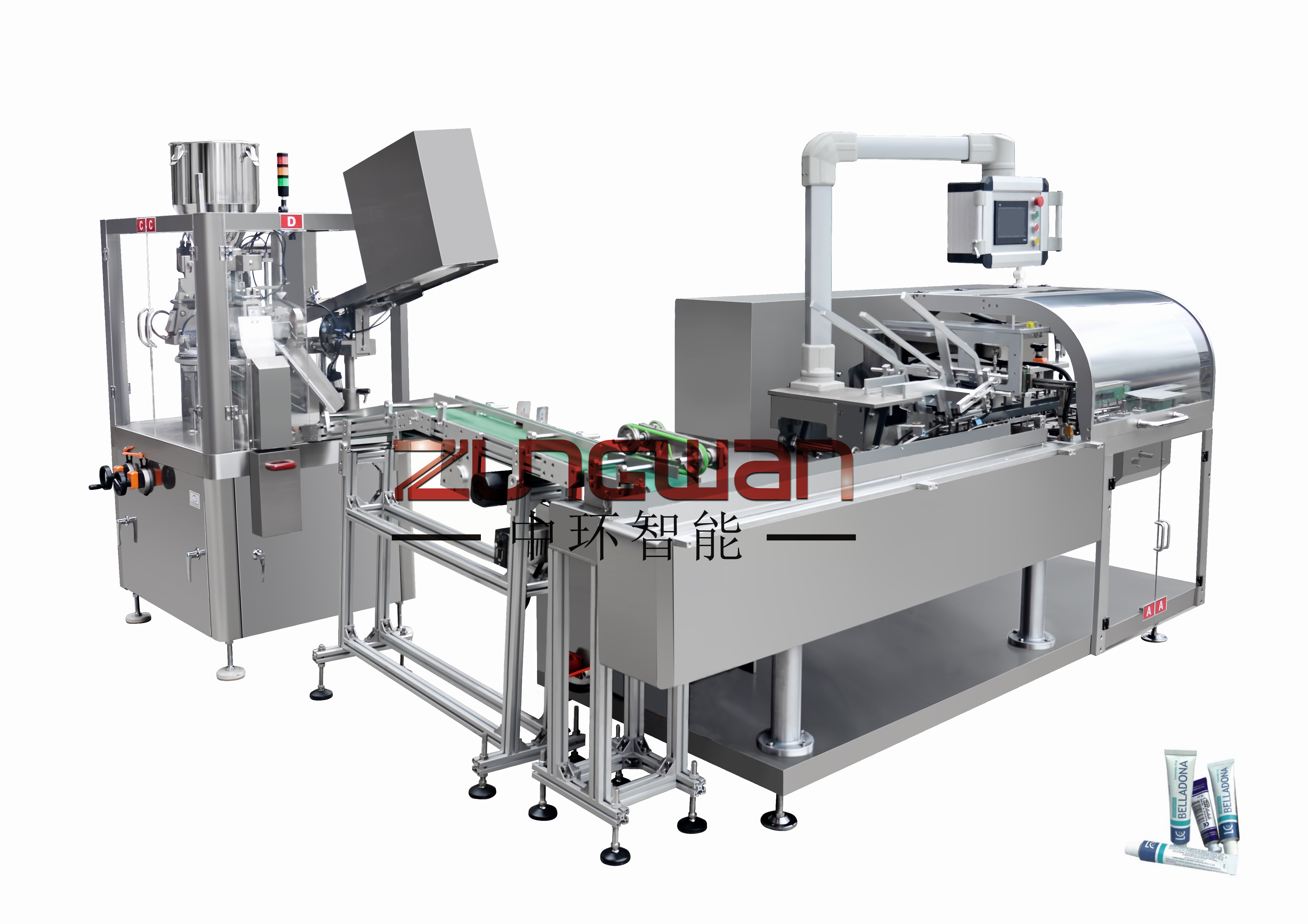

Wenzhou Zungwan Intelligent Machine Co.,Ltd. is the professional equipment manufacturer to keep researching and developi

Pharmaceutical Filler and Capper, whether semi-automatic or fully automatic, will encounter more or less in the process

With the continuous development of our production life, the emergence of Pharmaceutical Filler and Capper has brought gr

The Mid-Autumn Festival is the second most important festival for a family reunion in China after the Spring Festival. B

With the increasingly fierce competition in the manufacturing and production of plastic bottles in the food and pharmace

Liquid Filling Machine is specially designed for filling easy-to-open bottles. It has a reasonable design, simple struct

The shampoo packing machine can pack shampoo very well,and also applicable for liquid or paste material, such as honey, fruit sauce, chili sauce, vegetable oil, water, wine, soy sauce, vinegar, detergent, hand sanitizer, disinfectant, shampoo, pesticide etc. Item NO.: LK-300ml Product Origin: China Shipping Port: Xiamen Lead Time: 7-14 days

In 1894, Friedrich Hesser developed the first pouch machine for packaging goods. And later in 1890, Michael Owens invented the first automatic rotary bottle-making machine which led to the glass container popularity from then on until the 1960’s. In the early 1900’s, plastics were then introduced into the packaging industry.

Automatic Oral Liquid Glass Pet Small BottleLiquid Equipment Filler Syrup FillingMachinePrice Cap Press Screw CappingandLabelingProduction Line Machine US

Length 50-253mm Tube Filling And Sealing Machine Aluminum Laminated Packaging. Product …

50-110mm Length Mascara Tube Labeling Machine 90pcs/Min. Concealer Bottom Labeler Lip Glaze Mascara Tube Labeling Machine- 2nd generation (GMJ-815S)), is designed according to sample cosmetic tubes for bottom labeling. Applications of tube labeling machine: It is an ...

5. A vacuum suction device is mounted for the tube filler

Product Details: 40 - 90 Pouches / Per Minutes. (Depending upon the Size) UNIQUE PACKAGING SYSTEMS supply Automatic Liquid Fill