We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for Intellectual High-viscosity Filler wholesale,

Filling And Pump Capping Machine manufacturer, Ultrasonic tube filler and sealer supplier, Cream Filling And Capping Machine wholesale, Nasal Spray Filling Machine factory, chilli sauce bag packing machine manufacturer, For further information, please do not hesitate to contact us. All inquiries from you will be highly appreciated., British, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you. Capping Machine operation, accuracy error, installation adjustment, equipment cleaning, maintenance, and other aspects a

The Mid-Autumn Festival is the second most important festival for a family reunion in China after the Spring Festival. B

We know that Labeling Machine brings great convenience to our production and life, so what are the working principles an

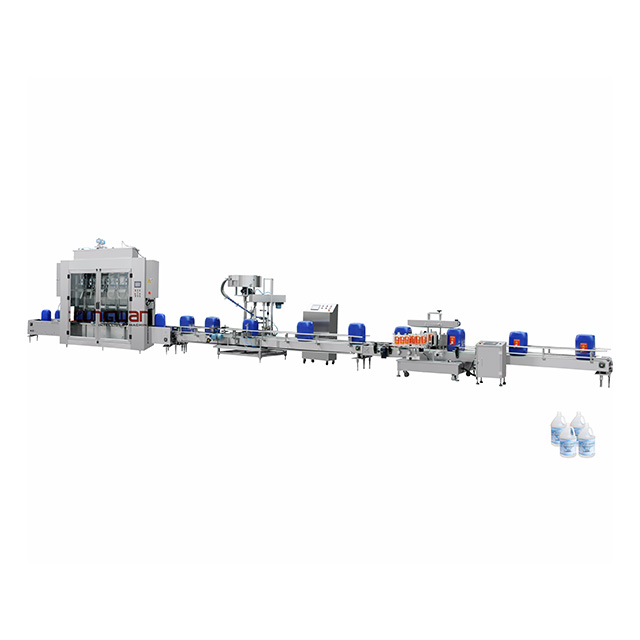

Korea East Asia Pharmaceutical Company, ordered a syrup filling line from our company, from bottle management - bottle w

After we purchase Pharmaceutical Filler and Capper, we need to install and debug Pharmaceutical Filler and Capper. Let's

Liquid Filling Machine is a kind of process machinery, its process characteristics are more obvious, for the design requ

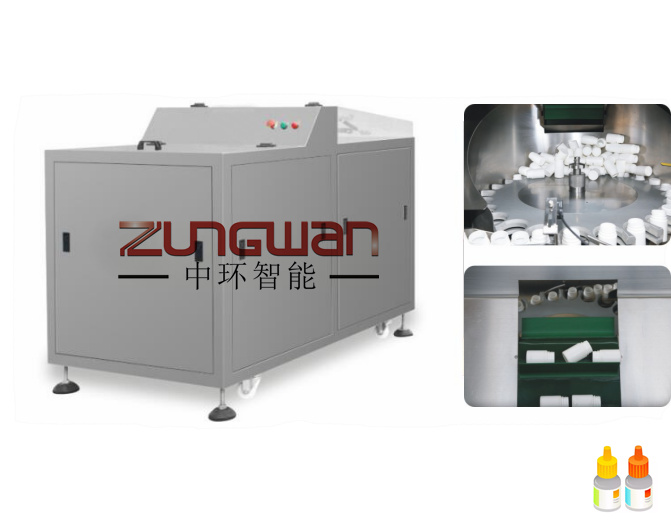

Bottle Unscrambler is suitable for automatic unscramble of plastic round bottles, flat bottles, and tube-top bottles. Di

After the Labeling machine sensor sends a signal that the labeling object is ready to be labeled, the drive wheel on the

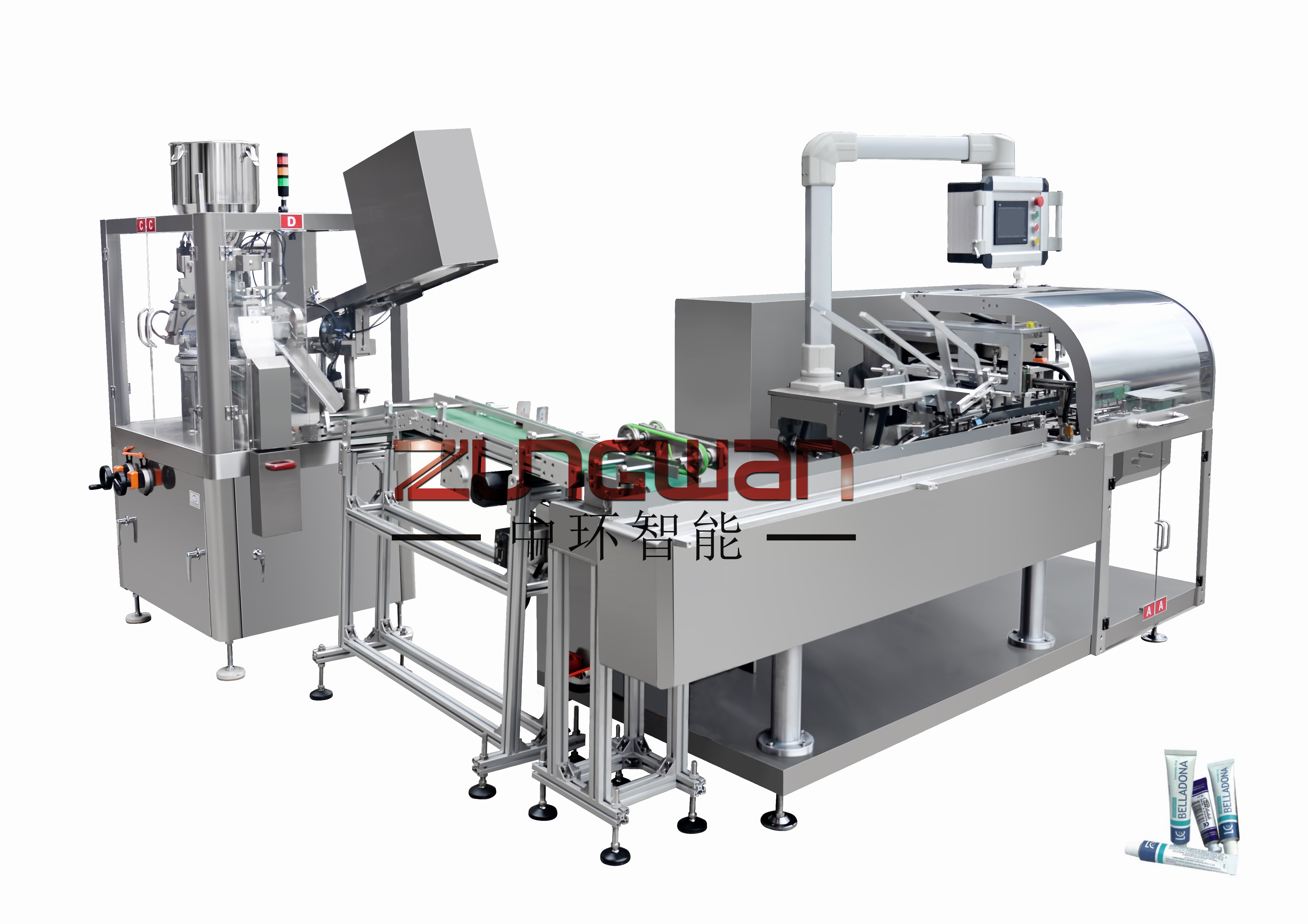

The metal tube filling and sealing machine can be used in the industries of pharmaceutics, foodstuffs, cosmetics, daily chemicals for smoothly and accurately filling all kinds of pasty and viscous fluid and the materials alike, into soft metal tubes and then carrying out tube end folding, sealing and lot number printing.

Dish Washing Liquid Filling Machine Automatic Cooking Oil Dish Washing Hand Soap Shampoo Cream Bottle Weighing Liquid Filling Machine Ready to Ship

Details and Price about Fully Automatic Tube Filling and Sealing Machine Auto Plastic …

Fruit Juice Packaging Machine in Ahmedabad, Gujarat

Pharmaceutical Filling Machine (21) Liquid Vial Filling Machine (22) Ampoule Filling Sealing Machine (22) Vial Powder Filling Machine (18) Infusion Bag Filling Machine (15) ISBM Machine (11) Glass Bottle IV Solution Production Line (17) BFS Machine (9) Automatic Capsule Filling Machine (25) Rotary Tablet Press Machine (28) Pharmaceutical ...

Automatic Pharmaceutical Syrup Filling Machine 10ml to 1000ml Liquid Filler Up to 5 years …

Automatic Tube Filling And Sealing Machine adopts 12-station design and is suitable for all kinds of folding pack for metal tube. It can easily pack the plastic tube and the metal tube ... automatic filling and sealing machine YBQ series liquid bottle for water

With this integral silicone rubber, Leidex has been equipped with high technical skills, and are able to produce regular, slim, swirl, marble and multi-color lipsticks. Powder Leidex was the first to succeed in developing a servo press deliberate …